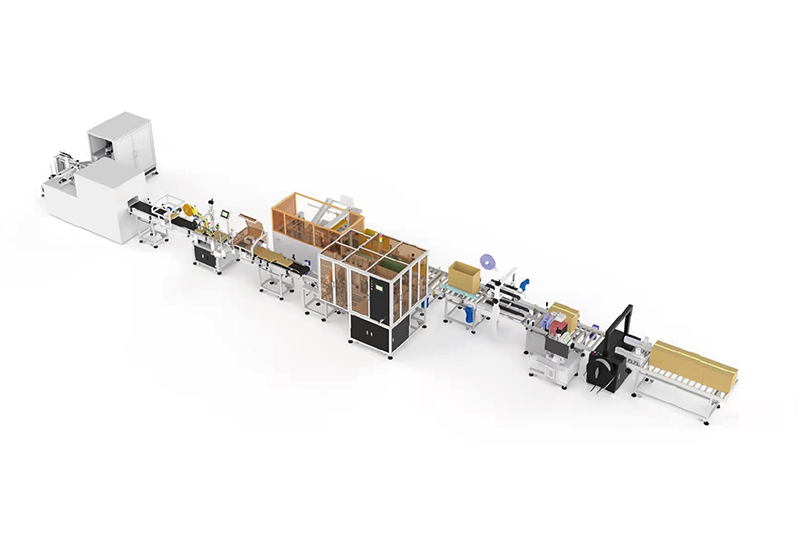

Streamline Your Output: Components of a Complete and Efficient Packaging System

This article explains how a complete packaging line operates as an integrated, perfectly synchronized system. From case erecting and checkweighing through filling, labeling, and sealing, and finally to robotic palletizing and stretch wrapping, every machine plays a vital role in maintaining a smooth production flow.

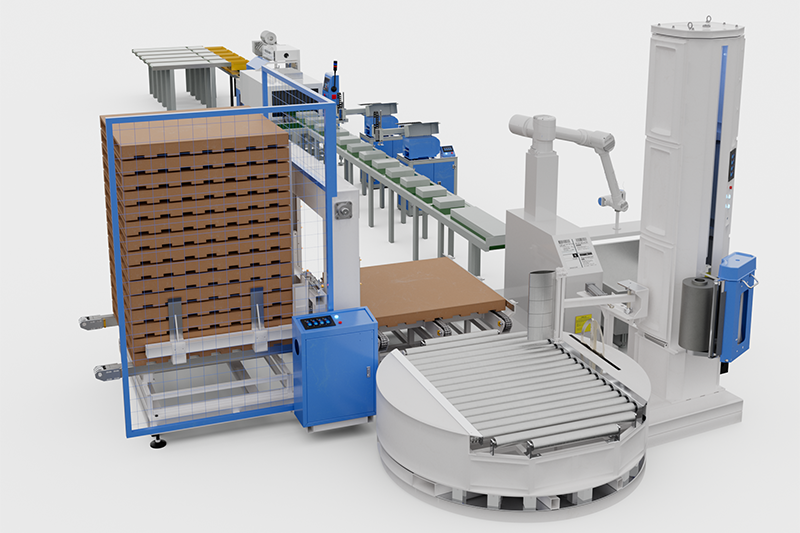

Beyond Heavy Lifting: The ROI of Integrating Robotic Palletizers and Stretch Wrappers

This article explores how robotic palletizers and automatic stretch wrappers transform end-of-line packaging operations. By automating palletizing and load securing, businesses gain higher throughput, greater accuracy, improved safety, reduced product damage, and a more flexible production setup.

The Ultimate Guide to End-of-Line Automation: Case Erecting, Sealing, and Palletizing

This article outlines how end-of-line automation transforms manual case erecting, sealing, palletizing, and wrapping into a fully streamlined, high-performance workflow. By integrating case erectors, sealers, robotic palletizers, and automatic stretch wrappers, businesses eliminate labor bottlenecks, improve product integrity, reduce material waste, and significantly increase throughput.

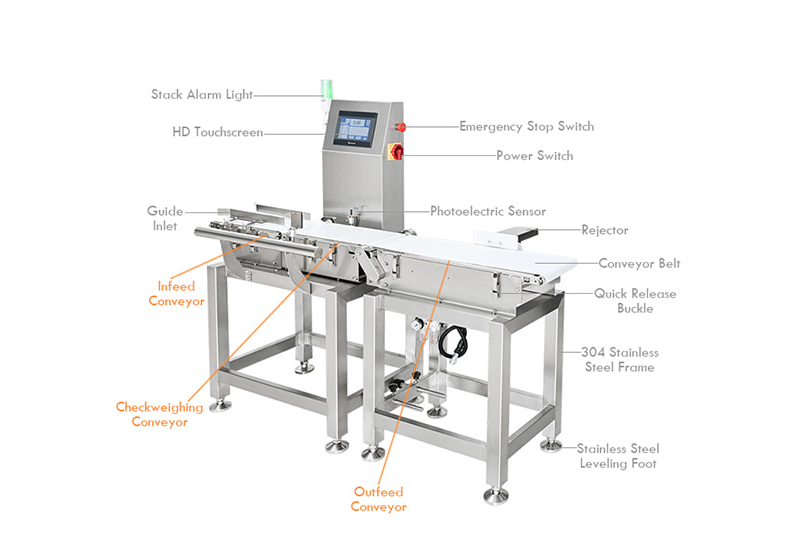

Maximizing Efficiency: Integrating Checkweighers into Your Packaging Workflow

A checkweigher is a crucial automated tool for modern packaging lines, providing rapid, accurate weight checks, automatic rejection of non-compliant products, seamless integration, and valuable production data.

How to Build a Fully Automated Packaging Line: Unboxing to Palletizing

This article explains how a fully automated packaging line integrates case erectors, checkweighers, auto-filling systems, labelers, case sealers, palletizing robots, and stretch wrappers into one seamless system. It details each stage from box forming to final load stabilization, outlining how automation removes manual bottlenecks, enhances accuracy, improves traceability, and significantly reduces labor and material costs.