Intelligent Egg Packing Line with Gentle Handling & Full Automation

Featuring coordinated robotic arms, automated inner sponge placement, precise egg grouping, and real-time labeling, this Industry 4.0-enabled solution delivers high accuracy, low breakage rates, and efficient material flow.

What is Egg Packaging System?

An Egg Packaging System is a fully integrated, automated end-of-line packaging solution specifically engineered for handling fragile egg products with maximum precision and minimal breakage. By combining robotic handling, buffered protective material placement, and Industry 4.0–ready control architecture, the system enables high-speed, consistent egg packing while significantly reducing reliance on manual labor.

The production line automates the complete workflow from carton erection to final palletizing. Flat cartons are first erected and prepared, followed by the automatic placement of bottom protective sponge layers. Egg groups are then conveyed and accurately packed into cartons using high-precision robotic packing hands, specifically designed for delicate product handling. To ensure comprehensive protection during transportation, top sponge layers are automatically positioned before the cartons proceed through flap folding, sealing, and H-type reinforcement sealing.

In the final stages, the system integrates real-time printing and labeling to apply logistics and traceability labels directly onto each carton, ensuring seamless downstream distribution. Robotic palletizing completes the process by stacking finished cartons onto pallets in a stable and repeatable pattern, creating transport-ready loads without manual intervention.

By automating critical handling points and integrating buffering materials throughout the packaging process, the Egg Packaging System significantly reduces egg damage rates, improves packaging consistency, and enhances overall production efficiency. This scalable and future-ready solution provides egg producers and processing facilities with a solid foundation for high-volume automated egg packaging operations, fully aligned with modern smart factory and Industry 4.0 requirements.

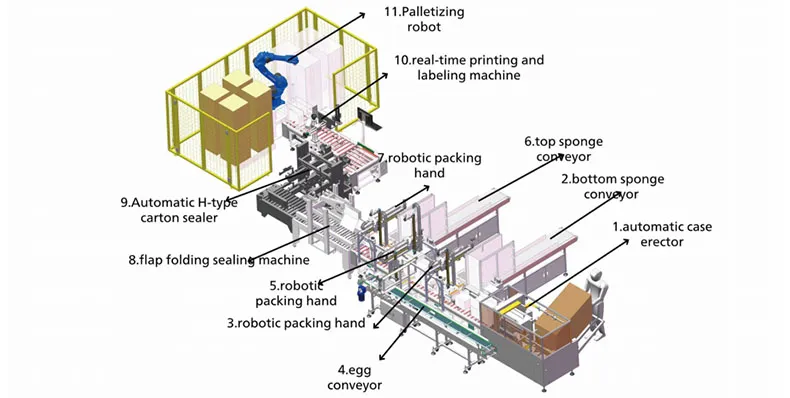

Egg packing Line Solution Components

Introduction

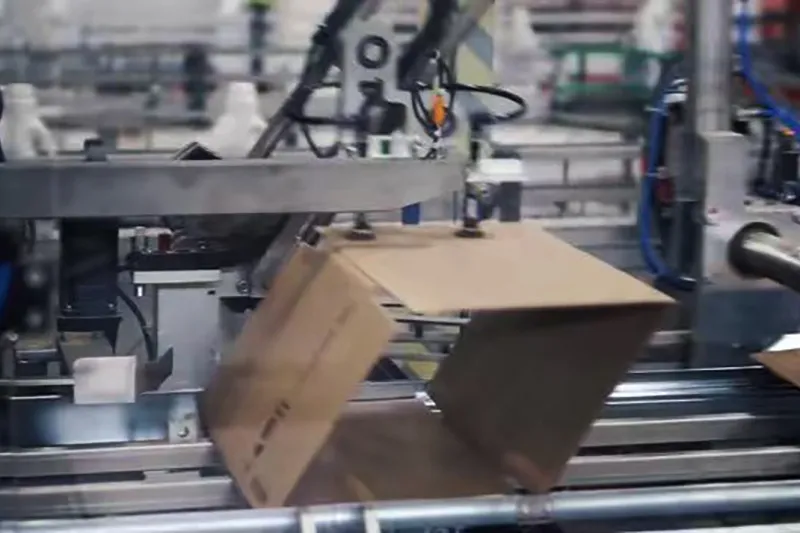

1.Automatic case erector:

It essentially transforms flat box blanks into usable containers, often using tape

or glue to seal the bottom flaps.

2.Bottom sponge conveyor:

Convey bottom inner sponge

3.Robotic packing hand:

packing bottom inner sponge into box.

4. Egg conveyor:

convey egg group.

5. Robotic packing hand:

Packing egg group.

6. Top sponge conveyor:

Convey top inner sponge

7.Robotic packing hand:

Packing top sponge

8.Flap folding case sealing machine:

Automate the entire carton sealing process, from carton erection to flap foldingand sealing,requiring minimal manual intervention.

9.H shape box sealer

10.Real-time printing and labeling machine:

Print the express delivery logistics label in real time and affix it to the box.

11.Palletizing robot:

An automated robotic system used to stack products onto pallets, typically at theend of a production line.

Trends and Global Necessity

The global manufacturing landscape is accelerating into the Industry 4.0 era, where Cyber-Physical Systems (CPS), IoT connectivity, and intelligent automation are redefining how production lines operate. For fragile food sectors such as egg processing, this transformation is no longer optional but a strategic necessity. The shift toward fully automated egg packaging systems is driven by several converging global trends that demand higher efficiency, consistency, and resilience across end-of-line operations.

Rising Labor Costs

Global manufacturing labor costs continue to rise at an unsustainable pace, while the availability of skilled operators for repetitive, high-risk tasks is steadily declining. In egg packing operations, manual handling not only increases labor dependency but also elevates the risk of product damage and inconsistent output quality. By replacing labor-intensive processes with a high-efficiency automated egg packaging line, producers can significantly reduce operating costs, stabilize production capacity, and achieve predictable long-term returns on investment.

Fragmented Customer Demands & E-commerce

Stricter environmental regulations, rising energy costs, and ongoing supply chain volatility are forcing manufacturers to rethink efficiency at the system level. Intelligent egg packaging solutions reduce material waste, optimize energy consumption, and minimize packaging-related carbon footprints through precise robotic handling and optimized process control. Digital monitoring and data-driven optimization further enhance supply chain resilience, allowing producers to respond quickly to disruptions while maintaining consistent packaging quality.

Environmental Regulations & Supply Chain Volatility

Global climate policies and supply chain disruptions demand a more resilient and sustainable manufacturing approach. Intelligent packaging machinery solutions mitigate the impact of new regulations, such as carbon tariffs, by reducing energy consumption by over 20%. Technologies like digital twins are now vital for enhancing supply chain response, allowing businesses to navigate disruptions while optimizing material usage across their end-of-line packaging solutions.

Strategic Industry 4.0 Investment

The rapid global adoption of Industry 4.0 technologies reflects a clear consensus: intelligent automation is a foundation for long-term competitiveness. For egg producers, investing in integrated, Industry 4.0–ready egg packaging lines enables real-time production visibility, data-driven decision-making, and seamless integration with upstream grading and downstream logistics systems. These capabilities are essential for building scalable operations that can adapt to evolving market and regulatory demands.

Enhanced Workplace Safety & Ergonomics

Egg packing involves repetitive handling, lifting, and precision placement—tasks that pose ongoing safety and ergonomic risks in manual environments. Advanced robotic egg packaging systems significantly reduce human intervention at critical handling points, lowering injury rates and improving workplace safety. By deploying robotic packing and palletizing solutions, manufacturers not only meet international safety standards but also reinforce a responsible, future-oriented operational image.

Key Benefits of an Automated Egg Packaging System

An automated Egg Packaging System enhances efficiency, lowers costs, and delivers consistent, high-quality egg packaging through intelligent automation.

Increased Efficiency

Full-line automation significantly accelerates the egg packaging process by synchronizing carton erection, buffered material placement, robotic packing, sealing, and palletizing. This integrated workflow reduces cycle times, minimizes bottlenecks, and maximizes throughput, ensuring stable high-speed production with minimal downtime.

Lower Operating Costs

By substantially reducing manual handling and minimizing packing errors, the automated egg packaging system helps cut labor expenses and material waste. Optimized carton usage and precise robotic placement further enhance cost efficiency, delivering a strong and predictable return on investment.

Consistent and High-Quality Packaging

Robotic handling and automated process control ensure uniform placement of eggs and protective sponge layers in every carton. This eliminates variability caused by manual operations, resulting in consistent packaging quality, improved product protection, and reduced damage rates across all production batches.

Reduced Labor Dependency

With robots performing repetitive, delicate, and physically demanding tasks, the system significantly reduces reliance on manual labor. This not only improves workforce utilization but also lowers the risk of workplace injuries, creating a safer and more ergonomic production environment.

Scalable and Flexible System Architecture

The modular design of the egg packaging line allows manufacturers to scale capacity as demand grows or adapt quickly to new carton sizes, egg configurations, and packaging formats. This flexibility supports both current production needs and future expansion without major line restructuring.

Sustainability

Through precise control of carton handling, buffering materials, and sealing processes, the system minimizes material waste and optimizes energy consumption. These efficiencies contribute to more sustainable egg packaging operations while supporting compliance with evolving environmental regulations.

Why Choose Joyda?

Industry 4.0 Integration

Our egg packaging systems feature Industry 4.0 architecture, enabling real-time monitoring, predictive maintenance, and seamless integration with upstream grading and downstream logistics for smarter, more efficient operations.

Tailored Automation Solutions

Every egg production facility is different. Our automated egg packaging lines are fully customizable, allowing flexible configurations for carton types, egg groupings, buffering materials, and production capacities—without compromising gentle handling.

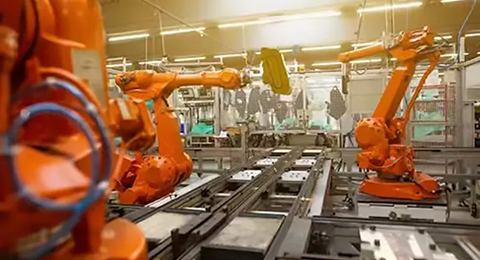

Proven Expertise Across Industries

With experience across food, electronics, medical, and industrial manufacturing, we bring mature system-integration capabilities to egg packaging applications—translating proven automation principles into reliable fragile-product handling solutions.

In-House Software Development

We develop and maintain our own ERP-integrated control software, providing full visibility and precise control over the entire egg packaging process. Real-time data tracking and stable system logic ensure consistent performance and smooth line coordination.

Commitment to Innovation and Quality

Continuous investment in R&D and quality management enables us to deliver reliable, high-performance packaging systems. From robotic handling accuracy to system stability, our solutions are engineered for long-term operation and consistent output quality.

End-to-End Customer Support

We provide complete lifecycle support, from system design and installation to training and after-sales service. Our engineering team ensures fast response, effective troubleshooting, and continuous optimization to keep your egg packaging line running at peak performance.

FAQ

An Egg Packaging System is a fully automated production line that handles carton erection, protective sponge placement, robotic egg packing, sealing, labeling, and palletizing—designed specifically for fragile eggs.

The line uses buffered bottom and top sponge layers, combined with precision robotic handling, to reduce vibration and impact, ensuring eggs are packed safely during automation.

Yes. The system is modular and customizable, allowing operators to adjust carton formats, egg quantities per carton, and sponge placement to suit various packing requirements.

Capacity depends on the configuration, but standard setups can pack thousands of eggs per hour while maintaining gentle handling and consistent output quality.

Absolutely. Our lines are equipped with Industry 4.0-ready software, enabling real-time monitoring, predictive maintenance, and integration with upstream grading and downstream logistics systems.

Automation synchronizes all stages—from carton erection to palletizing—reducing cycle times, minimizing manual labor, and maximizing throughput while maintaining product integrity.

Yes. The system is designed for flexible installation, with modular equipment and ERP-compatible control software, allowing smooth integration into existing egg processing or packaging operations.

Routine preventive maintenance includes cleaning conveyors, checking robotic grips, and monitoring system sensors. Our software also supports predictive maintenance to minimize unplanned downtime.

By optimizing carton usage, sponge placement, and precise robotic handling, the system reduces material waste and energy consumption, supporting environmentally friendly packaging practices.

We offer end-to-end customer support, including consultation, installation, staff training, troubleshooting, and ongoing service to ensure the line operates efficiently from day one.