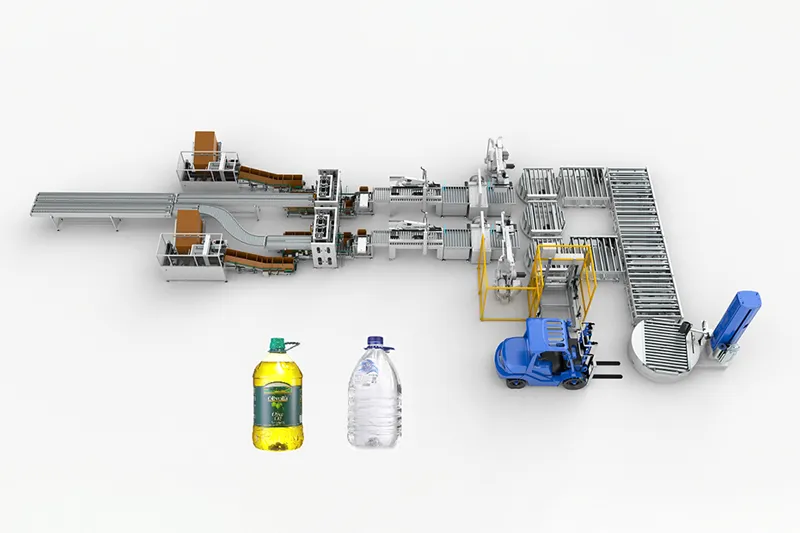

Cooking oil packing production line

A benchmark for Industry 4.0 smart manufacturing, this automatic packaging production line is engineered for a high-speed capacity of 4,000 bottles per hour. By replacing 19–21 manual labor positions, the system achieves a full ROI within one year, transforming traditional facilities into modern, intelligent workshops with perpetual operational savings equivalent to the wages of 20 workers.

What is Cooking oil packing production line?

The Cooking Oil Packing Production Line is a fully automated secondary packaging system designed to process filled edible oil containers through case forming, packing, sealing, labeling, and palletizing. Powered by Industry 4.0 smart manufacturing, the line connects each module through centralized control and real-time data tracking—ensuring high precision, operational hygiene, and full traceability across the entire automatic packaging production line.

The operation begins with the Bottle Feeding and Automatic Sorting Unit, where filled and capped bottles are received and oriented for the packaging phase. The system supports high-speed conveying of various bottle formats, ensuring a steady supply to the downstream modules. Integrated functions such as Vision Inspection and Barcode Verification are utilized to ensure that only properly filled and labeled bottles proceed to the secondary packaging stage, maintaining strict quality standards for food-grade products.

Next, the bottles move into the Case Packing or Shrink Bundling modules, where products are systematically organized into shipping configurations. The workflow is supported by high-performance Automatic Case Erectors that form sturdy cartons with precision. Following the loading process, Flap Folding Sealers and integrated Check Weighers with rejection systems verify the weight and integrity of each package. For marketing consistency and regulatory compliance, optional labeling modules can be integrated to handle sleeve or wrap labeling on the secondary containers.

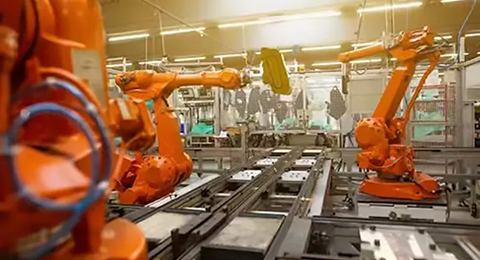

The process concludes with a high-capacity Robotic Palletizing System, designed to handle the heavy-duty requirements of filled oil cartons. This end-of-line packaging solution provides stable, systematic stacking on pallets, optimized for warehouse automation and efficient logistics transfer. By combining advanced robotics with IoT-based monitoring, this Cooking Oil Packing Production Line significantly reduces manual labor, eliminates handling errors, and ensures a consistent, high-throughput workflow for modern food processing factories.

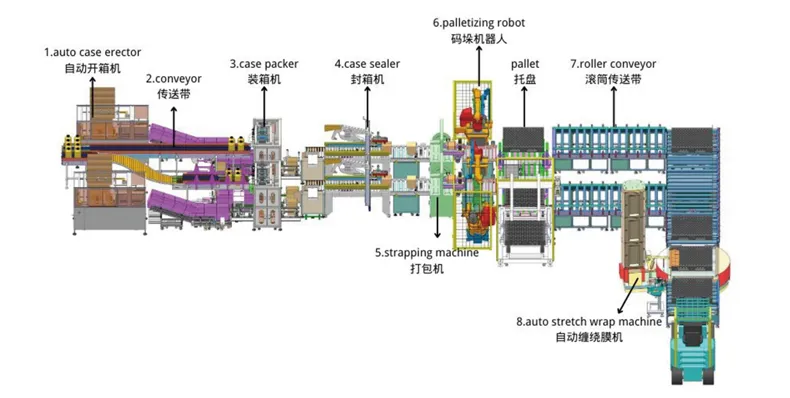

Cooking oil Line Solution Components

Introduction

1.Automatic case erector :

It essentially transforms flat box blanks into usable containers, often using tape

or glue to seal the bottom flaps.

2.Conveyor :

Used for transporting product.

3.Case packer machine:

A machine used in automated packaging lines to group and load products intoshipping cases,typically made of corrugated cardboard.

4.Case sealer :

A machine used to automatically seal cardboard boxes or cases, typically withadhesive tape.

5.Strapping machine :

A machine used to automatically seal cardboard boxes or cases, typically withadhesive tape.

6.Palletizing robot :

An automated robotic system used to stack products onto pallets, typically at theend of a production line.

7.Roller conveyor:

A type of conveyor system that uses rollers mounted on a frame to transportitems, either by gravity or with powered mechanisms.

8.Automatic stretch wrap machine:

A piece of equipment used to apply stretch film to a palletized load, securing itfor storage and shipping.

Trends and Global Necessity

The manufacturing landscape is rapidly evolving into the Intelligent Revolution, known as Industry 4.0. Driven by Cyber-Physical Systems (CPS), IoT, and AI, this shift has become a fundamental necessity for businesses to thrive globally. The imperative for advanced automation, especially within the automated packaging machine sector, is underscored by several critical trends shaping the future of automatic packaging production lines for the edible oil industry.

Rising Labor Costs

Unsustainable increases in global manufacturing labor costs—averaging 5% to 8% annually—are a primary driver for automation. In high-output edible oil facilities, manual packing and palletizing are labor-intensive and increasingly costly. By replacing manual tasks with efficient packaging machinery, companies can directly reduce overheads and ensure long-term economic viability. This strategic investment in an automatic packaging line provides a proven ROI, often achieved within a single year by addressing volatile operational expenses.

Fragmented Customer Demands & E-commerce

The explosive growth of e-commerce has led to increased SKU diversification and a rise in smaller, customized orders, such as different bottle sizes or multi-pack configurations. Traditional, inflexible production lines with lengthy changeovers are becoming obsolete. Modern automatic packaging production lines are engineered for this new reality, featuring modular designs that enable rapid changeovers in minutes—crucial for agile market adaptation and efficient fulfillment of fragmented demands.

Environmental Regulations & Supply Chain Volatility

Global climate policies and supply chain disruptions demand a more resilient and sustainable approach to secondary packaging. Intelligent packaging machinery solutions mitigate the impact of new regulations, such as carbon tariffs, by reducing energy consumption by over 20%. Technologies like digital twins are now vital for enhancing supply chain response, allowing oil producers to navigate disruptions and optimize material usage across their custom integrated packaging lines.

Strategic Industry 4.0 Investment

The multi-trillion-dollar global Industry 4.0 market, growing at nearly 19% CAGR, reflects widespread adoption across major manufacturing hubs. For large-scale oil processing facilities, the transition toward custom integrated packaging lines is a strategic imperative for operational excellence. Proven results confirm that intelligent automation is the foundation for maintaining a global competitive edge and ensuring the long-term resilience of a modern packaging production line.

Enhanced Workplace Safety & Ergonomics

Beyond regulations, manufacturers are increasingly focused on reducing workplace injuries associated with heavy lifting and repetitive manual packing. Advanced automatic packaging production lines utilize precision robotics and "right-sized" packaging to minimize material waste. By integrating solutions like robotic palletizers to handle heavy oil cartons, manufacturers can lower both shipping costs and carbon footprints, meeting growing environmental and safety expectations while building a more responsible brand image.

Benefits of Cooking oil packing production line

In the evolving publishing and logistics landscape, intelligent book packaging machine systems are no longer just an operational upgrade but a strategic imperative. By addressing core challenges from production to delivery, these advanced solutions deliver multifaceted benefits, ensuring product integrity, operational efficiency, and enhanced customer satisfaction.

Fully Automated Process for Cooking Oil Packing

The cooking oil packing line automates every aspect of the packaging process—from bottle forming, filling, capping, to labeling, ensuring a seamless operation with minimal human intervention.

High Efficiency with Industry 4.0 Integration

Leveraging Industry 4.0 technologies, the production line is equipped with real-time data monitoring, intelligent control, and advanced sensors to ensure high efficiency, speed, and accuracy in every step of the packaging process.

Precision in Carton Packing and Sealing

The Cooking Oil Packing Production Line delivers high accuracy in both carton loading and carton sealing. Automated systems position each bottle precisely into the case, while the sealing unit ensures consistent, secure closure. This precision minimizes errors, prevents carton deformation, and maintains reliable packaging quality throughout high-volume operations.

Enhanced Quality Control and Inspection

Built-in quality control checkpoints such as inline weighing, vision inspection, and leak testing ensure that each bottle meets the highest quality standards before being sealed and packed.

Flexible Bottle Handling and Customization

The production line supports various bottle shapes and sizes, offering flexibility to manufacturers. The system can also handle additional packaging features like labeling, batch coding, and date marking.

Improved Traceability and Inventory Management

With smart data integration, the production line offers complete traceability, from raw materials to finished products, facilitating better inventory management and traceability for compliance and reporting.

Why Choose Joyda?

Industry 4.0 Ready

We lead with intelligent automation. Our in-house software integrates with your ERP, leveraging AI and IoT for seamless data flow and autonomous decision-making. This means flexible production, real-time optimization, and significant cost control, cutting changeover times to 15 minutes and energy use by 22%.

Packaging & Tape Application Experts

Specializing in tape applicators and full packaging systems, we solve common line issues like jams and slow seals. Our strength is blending robust hardware with smart software for smooth, hitch-free operations.

Proven Cost & Efficiency Gains

Our automation reduces direct labor costs by 30%. With MES-driven digital control, we cut fault response time to under 30 seconds, boosting overall efficiency by over 40%. Clients see product damage drop from 3% to 0.2% and unplanned downtime cut by 75%.

Flexible & Rapid Changeover

Our modular design allows packaging specification changes in just 15 minutes, down from hours. We adapt to diverse needs, handling various product sizes and bag shapes, enabling quick product type changes and dynamic formula management.

Robust In-House Manufacturing & Testing

Our 30,000 sqm Dongguan factory produces all equipment with stringent QC. We conduct real-world tests to ensure stability, preventing unexpected stops and ensuring your lines run steadily.

Global Compliance & Trusted Partnerships

Our machines meet global standards (ISO 9001, CE, UKCA, EAC, AS/NZS, NOM), ensuring smooth worldwide operations. Our long-term partnerships with manufacturers across Asia, Europe, and Mexico validate Joyda's reliability and value.

FAQ

The line is designed to accommodate a variety of bottle shapes and sizes, including both glass and plastic bottles. The system is flexible and can be easily adjusted to meet different production requirements.

Our automatic filling machines utilize precise volumetric control systems, equipped with advanced sensors to ensure uniform filling of every bottle, maintaining consistency and reducing waste across production batches.

Yes, multiple quality control measures are in place, including inline weighing, vision inspection systems for label placement and bottle integrity checks, and leak detection to guarantee each bottle meets the required standards before it is sealed and packed.

The production line is compatible with various cap types, including screw caps, snap-on caps, and other closures. The capping module is adjustable to handle different closure mechanisms depending on the bottle and cap specifications.

Yes, the system is designed to scale with your production needs. It can be easily adjusted to accommodate high-speed or low-speed production, making it suitable for both large-scale manufacturing and smaller batch runs.

The line utilizes advanced bottle handling systems such as conveyor guides, vibration-free platforms, and precise gripper systems that secure the bottle during filling and capping processes, ensuring stability and preventing spills or mishandling.

The system is designed for low maintenance, but it does include predictive maintenance capabilities. Sensors monitor the health of each machine, alerting operators to any potential issues before they cause downtime, thus improving overall reliability.

Yes, the line is fully compatible with other production systems, including ERP, MES, and WMS. It features real-time data integration, allowing seamless connection for better inventory tracking, reporting, and operational visibility across the entire production process.

The system is designed for full traceability, from raw material intake to final product. It integrates with data collection software, enabling manufacturers to track each batch and ensure compliance with safety and regulatory standards.

The Cooking Oil Packing Production Line is designed with energy efficiency in mind. Through optimized automation, energy consumption is minimized while maintaining high production speeds and efficiency, ultimately lowering operational costs for manufacturers.