Industry 4.0 Solutions for Packaging Lines

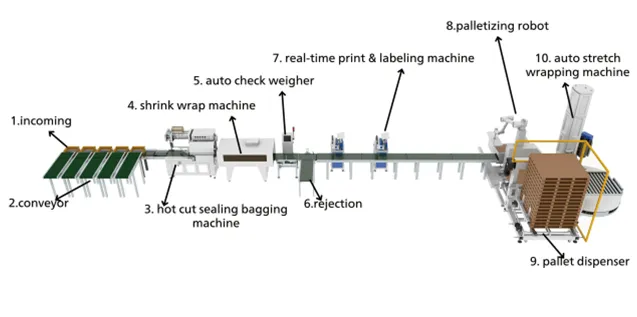

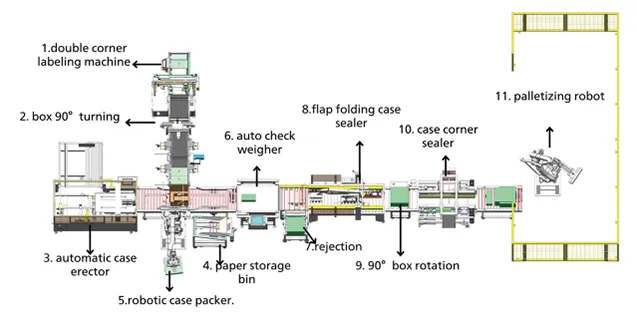

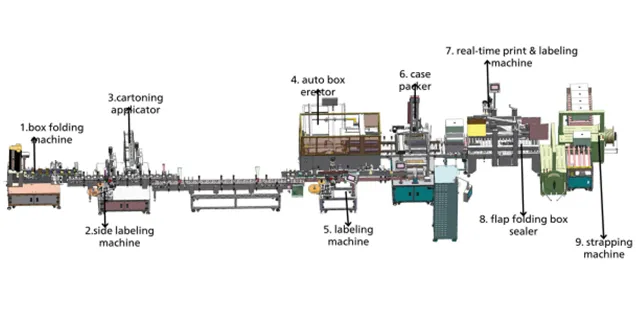

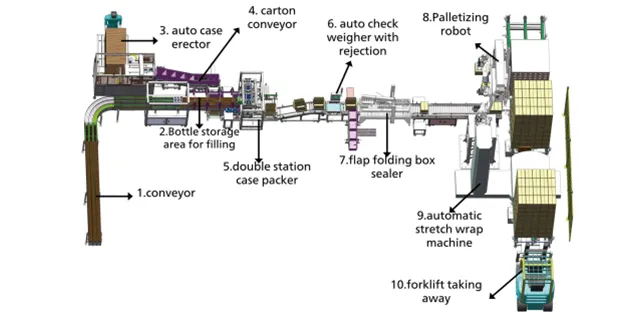

Industry 4.0 is transforming the way automatic packaging production lines operate. By integrating advanced packaging automation solutions, robotics, and real-time data, smart factories in the print and packaging sector achieve higher productivity, reduced waste, and longer equipment lifecycles. These intelligent end-of-line packaging solutions enable every stage—from case packing, labeling, and bagging to robot palletizing—to operate with precision and minimal human intervention.

What Industry 4.0 Means for Packaging

Enhanced Product Quality

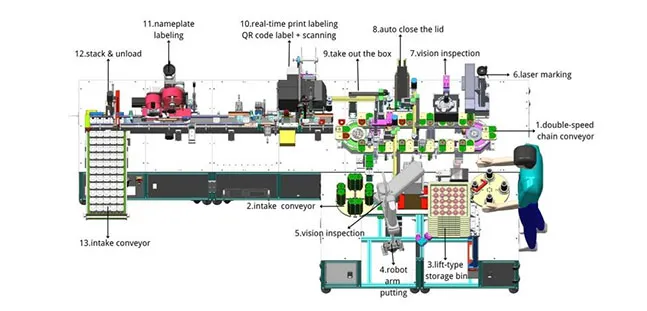

Automated inspection, digital monitoring, and precise robotic handling within our automatic packaging lines ensure every package meets consistent quality standards—drastically reducing defects and improving customer satisfaction.

Increased Productivity

Interconnected machines and synchronized workflows shorten cycle times and increase packaging throughput. Our packaging automation solutions enable a faster response to fluctuating production demands with higher efficiency.

Lower Operational Costs

Predictive maintenance and optimized resource allocation minimize downtime and maintenance expenses. By implementing smart end-of-line packaging solutions, you achieve higher output with significantly fewer resources.

Reduced Risk

Real-time monitoring systems detect anomalies and prevent errors before they occur, ensuring stable packaging system performance and creating safer, more reliable working conditions for your staff.

Greater Innovation

Smart data analytics and modular automation make it easier to adapt your automatic packaging production line to new products, materials, or designs—ensuring your business stays ahead of rapidly evolving market trends.

Higher Revenue

Improved efficiency and reduced material waste in your turnkey projects translate directly into higher profit margins and a faster return on investment (ROI) for your packaging facility.

Stronger Competitive Edge

Intelligent scheduling and data-driven decision-making accelerate your time-to-market. Joyda’s advanced technology gives you a distinct advantage over competitors in the fast-paced packaging industry.

The Digital Backbone of Industry 4.0

AGILE

Smart automatic packaging production lines adapt quickly to diverse product types, sizes, and changing schedules. By integrating automated setup and digital recipe management, changeovers for various packaging automation solutions take minutes instead of hours—maximizing uptime and ensuring peak production flexibility for your facility.

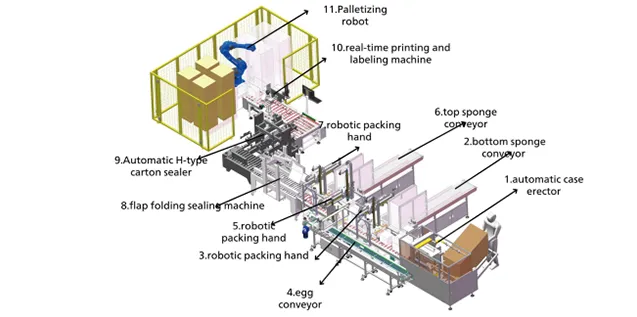

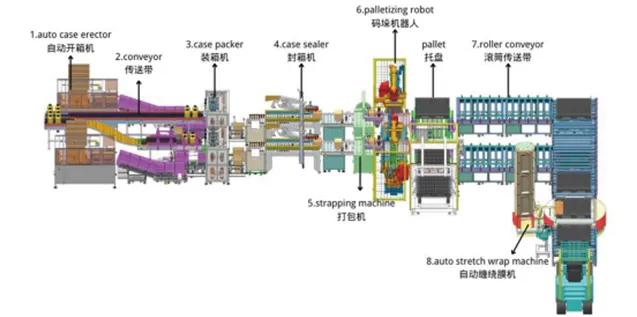

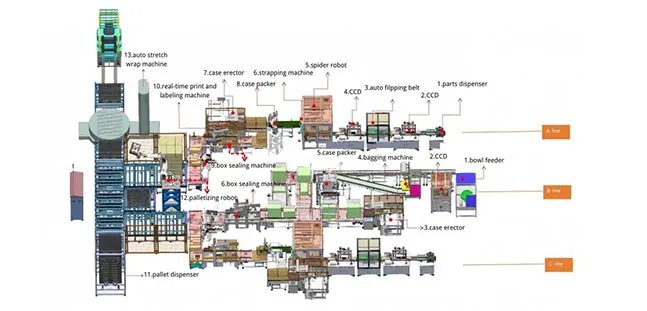

CONNECTED

Every device within our end-of-line packaging solutions, from case packers to robot palletizing systems, is digitally interconnected. This seamless communication enables real-time coordination, full traceability, and centralized process control across the entire automatic packaging line flow.

TRANSPARENT

Live production dashboards visualize critical performance data—including OEE, output rates, and material usage. This transparency provides operators with clear, actionable insights into the automatic packaging production line, facilitating immediate optimization and more accurate, data-driven decision-making.

OPTIMIZED

Through intelligent scheduling, automated quality checks, and energy-efficient operations, our turnkey packaging projects run with minimal human intervention. These optimized systems achieve consistent performance and significantly reduce operational waste across the packaging production line.

PROACTIVE

Predictive systems detect potential anomalies before downtime occurs. Maintenance tasks, material replenishment, and quality checks are automatically triggered within the packaging system, ensuring stable, uninterrupted performance for all your end-of-line packaging solutions.

Competitive Advantages of Industry 4.0

Automated Data Control

You gain full visibility across every stage of your automatic packaging production line—from material feeding to robot palletizing. Real-time data integration allows your operators to monitor performance and detect issues instantly, making rapid adjustments to keep the entire packaging system running at peak efficiency.

Consistent Packaging Quality

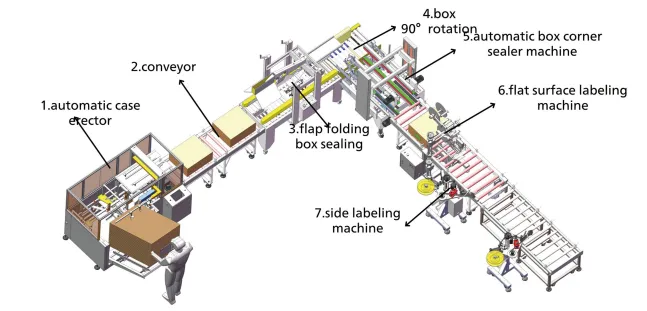

Ensure every package meets your consistent quality standards with automated inspection, labeling, and sealing systems. These packaging automation solutions provide stable, uniform performance that minimizes manual errors and significantly improves your final product presentation.

Predictive Maintenance

Avoid unexpected production stops with intelligent sensors and monitoring software that identify potential faults before they affect your output. Within your end-of-line packaging solutions, this proactive approach reduces unplanned downtime and extends the reliable lifespan of your packaging machinery.

Lower Production Costs

Maximize your resources and reduce reliance on manual labor through optimized workflows and smart resource allocation. Our turnkey packaging projects are designed to minimize waste and energy use, delivering measurable cost savings across your entire packaging production line.

Faster Changeovers

Respond quickly to changing market demands with digital recipe management and modular designs. Your automatic packaging line can adapt to different product formats in minutes rather than hours, ensuring flexible and uninterrupted production for multi-category packaging.

Sustainable Operations

Align your facility with global environmental goals through energy-efficient drives and reduced material waste. Our Industry 4.0 solutions help you achieve a more sustainable, low-carbon packaging process without sacrificing the high productivity your business requires.

Smart Packaging Solutions for Every Industry

FAQ

An Industry 4.0 packaging line integrates automation, robotics, and real-time data systems to achieve intelligent, flexible, and fully connected packaging operations. It enables higher efficiency, quality consistency, and data-driven control throughout the entire process.

By synchronizing machines such as case erectors, packers, labelers, and palletizers, the line reduces manual intervention and minimizes downtime. Intelligent scheduling and monitoring ensure continuous, high-speed packaging performance.

Our solutions are widely used in multiple industries, including food and beverages, books and printing, electronics, household products, cosmetics, and industrial components—offering customized packaging lines for each sector.mation.

Yes. With modular design and digital recipe management, the system allows fast changeovers between products of various dimensions, shapes, and packaging formats.

Sensors continuously monitor equipment performance and alert operators before potential issues occur. This helps reduce unplanned downtime and extend machine lifespan.

In most cases, yes. Our engineers can retrofit or connect your existing machines to the new digital network, allowing gradual transformation toward a fully automated smart factory.

Through optimized energy use, reduced material waste, and precise resource allocation, smart packaging lines help lower carbon emissions and support eco-friendly production goals.

We offer full lifecycle support—from system design, installation, and programming to remote diagnostics, operator training, and after-sales maintenance—to ensure long-term reliability and performance.