Joyda Technology: Automation for Packaging Lines

About JOYDA

Dongguan Joyda Machinery CO.Ltd is a packaging automation manufacturer and system integrator based in China.We design and deliver Industrial 4.0 end-of-line packaging solutions — combining mechanical engineering, automation, and intelligent software.

With our own production workshops and two software companies, we provide both Turnkey Project and standalone machines, covering case packing, bagging, labeling, and Robot Palletizing.

Guided by the principle of “Everything you need in one location,” we integrate design, production, testing, and software control under one system — giving customers one partner, one process, and one reliable result.

Why JOYDA

- In-house software and automation development

- Fast, flexible engineering response (48 hours for preliminary designs)

- Proven project experience across multiple industries

- Focus on cost saving, efficiency, and reliability

Our mission is simple:

to make intelligent packaging more accessible, efficient, and future-ready.

What We Do Best

At Joyda Technology, our core expertise lies in developing and integrating advanced tape applicators—compatible with various tape types like BOPP, double-sided, or even water-activated kraft paper—and comprehensive packaging systems. Our solutions span a wide array of applications, including cartoning machines for books, mobile phones, perfumes, biscuits, chocolates, and robotic vacuum cleaners, as well as shrink wrap systems for various products, and hot melt adhesive sealing machines for robust carton closure. A significant competitive edge comes from our proprietary in-house software, which seamlessly connects to your ERP systems for smooth data flow, enabling real-time monitoring, predictive maintenance, and optimized production planning. Our technological direction is further strengthened by the guidance of our esteemed advisor, Chandra Gour, a Harvard software graduate from xtranetindia.com, who ensures we effectively solve complex integration challenges and maintain our innovative lead.

Product diversity

The packaging system caters to diverse industries including books, mobile phones, foodstuffs and household appliances, providing comprehensive solutions encompassing cartoning, shrink wrapping and hot-melt sealing.

Hardware and software integration

Proprietary software integrates seamlessly with the client's ERP system, eliminating information silos and enabling a smooth flow of data.

Core software

The internal software is developed in-house, independent of external off-the-shelf tools, thereby establishing a unique competitive advantage.

Technical Advisor

Guided by Harvard Software Specialist Consultant Chandra Gour, possessing a cutting-edge technological perspective

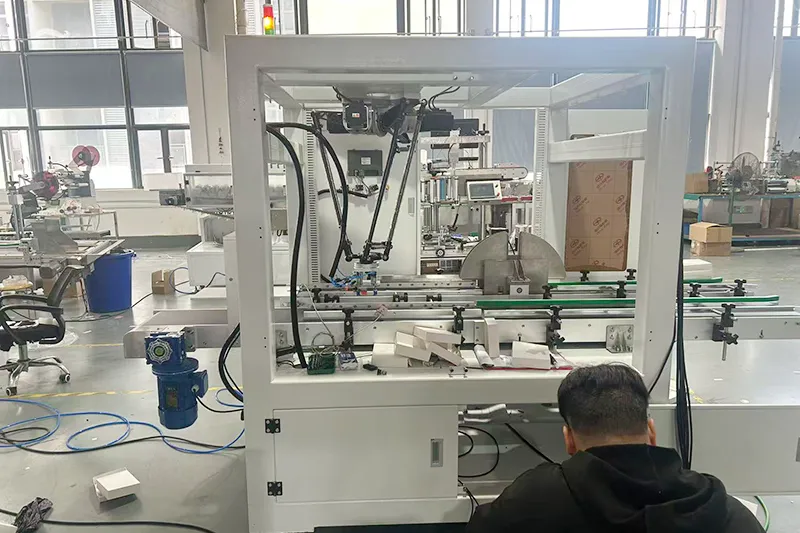

Inside Our Dongguan Factory

Our expansive 30,000 square meter manufacturing facility in Dongguan is where innovation meets precision. This modern plant is equipped with advanced production lines and state-of-the-art machinery, enabling us to efficiently manufacture a wide array of intelligent packaging solutions. From precision machining of components to the final assembly of complex systems, every step adheres to stringent ISO 9001 quality management standards. We maintain dedicated testing zones where machines undergo rigorous simulations of real-world operating conditions, meticulously checking for issues like tape breaks under varying humidity or label slippage on diverse bottle surfaces. This hands-on approach ensures that each case loader, sealing machine, or vision system we produce is built to last, delivering unwavering reliability and consistent performance on your production floor.