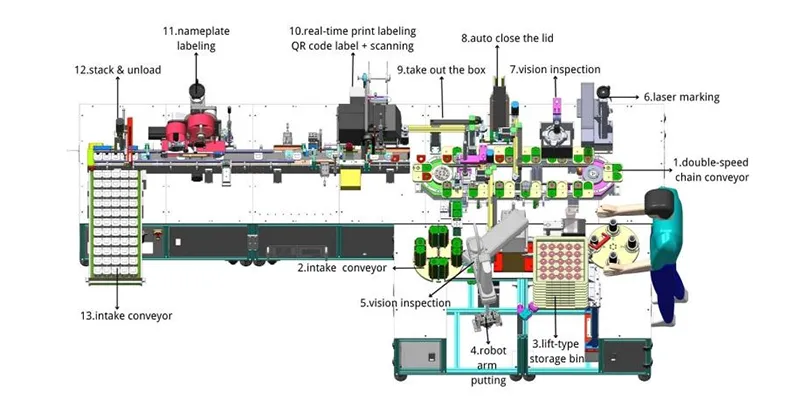

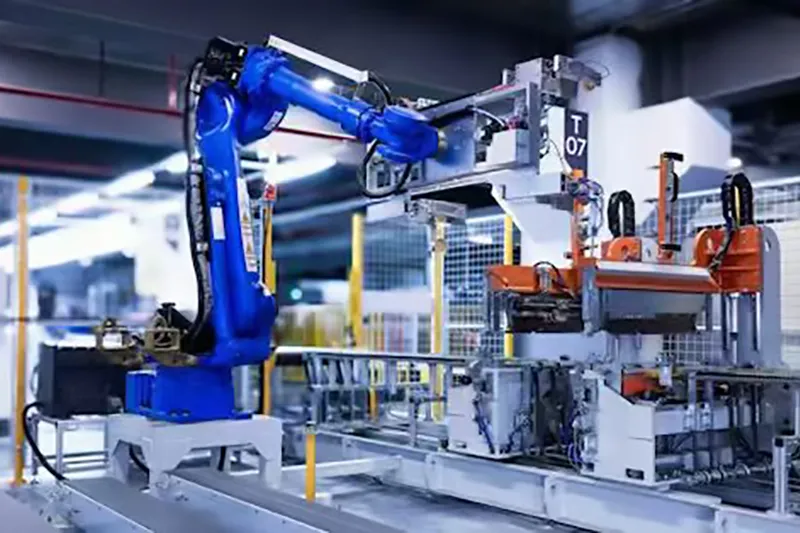

Fully Automated Flat Washer Packaging Line Designed for Precision and Efficiency

This fully automated flat washer packing line integrates robotic handling, dual-vision inspection, laser marking, and real-time labeling. The stations are enhanced with Industrial 4.0 elements such as data connectivity, process monitoring, and intelligent coordination, enabling more stable throughput, improved traceability, and consistent end-of-line performance.

What is a Flat Washer Packing System?

The Flat Washer Packing System is a fully integrated, end-to-end automatic packaging production line engineered to maximize operational efficiency while ensuring precise handling of small, fragile flat washer components. By combining high-performance packaging machinery with robotic arms, dual vision inspection systems, laser marking, and Industry 4.0 connectivity, this system achieves high-speed, accurate packing while significantly minimizing manual intervention throughout the workflow.

From the intake conveyor and lift-type storage bin to robotic placement, lid closing, and real-time labeling, the line streamlines the complete secondary packaging operation for flat washers. Dual vision inspection systems ensure both pre- and post-packaging quality control, while laser marking and QR code labeling guarantee permanent, traceable identification of each product. The final phase integrates stacking and unloading modules, providing a unified and reliable solution for transport-ready goods.

Implementing this automated system reduces labor costs, eliminates human error, and optimizes material usage. These end-of-line solutions enable faster production cycles, consistent product quality, and scalable performance, offering a future-proof foundation for modern flat washer packaging operations seeking maximum throughput and operational excellence.

Fully Automated Flat Washer Packaging Line Solution Components

Introduction

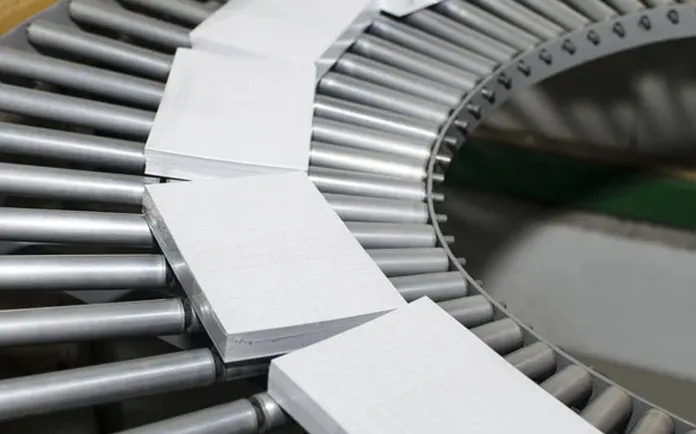

1.Double-speed chain conveyor:

Convey the flat washer box.

2.intake conveyor:

Convey the flat washer.

3.Lift-type storage bin:

Lifting bin that can store flat washers.

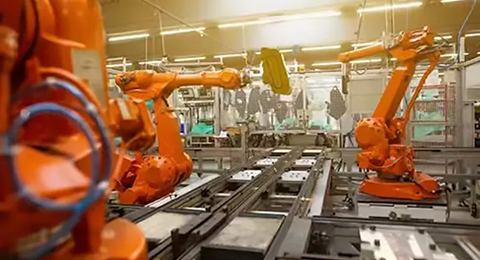

4.Robot arm putting:

Putting flat washer with automatic robot arm.

5.Vision inspection system:

Carry out quality inspection of the products through the camera.

6.Laser marking:

Uses a focused beamof light to create a permanent mark on the surface.

7.Vision inspection system:

Carry out quality inspection of the products through the camera.

8.Auto close the lid.

9.Take out the box.

10.Real-time print labeling QR code label + scanning.

11.Nameplate labeling.

12.Stack&unload:

Unloadinf and stacking the finished product.

13.Intake conveyor:

Convey the finished product.

Trends and Global Necessity

The global manufacturing landscape is rapidly evolving toward the Intelligent Revolution, commonly known as Industry 4.0. Driven by Cyber-Physical Systems (CPS), IoT, and AI, this shift has transitioned from a technological upgrade to a fundamental necessity for businesses to remain competitive. The rising demand for advanced packaging automation solutions, particularly within the automatic packaging machine sector, is underscored by several critical global trends.

Rising Labor Costs

Unsustainable increases in manufacturing labor costs—averaging 5% to 8% annually—serve as a primary driver for automation. By replacing manual, repetitive tasks with efficient packaging machinery, companies can significantly reduce overheads while ensuring long-term cost-effectiveness. This strategic investment in automatic packaging lines provides a proven ROI by addressing one of the most volatile and significant operational expenses in modern business.

Fragmented Customer Demands & E-commerce

The explosive growth of e-commerce has led to increased SKU diversification and a rise in smaller, customized orders. Traditional, inflexible production lines with 4 to 8-hour changeovers are increasingly obsolete. Modern book packaging machine systems and cartoning machine solutions are engineered for this new reality. Featuring modular designs and intelligent software, they enable rapid changeovers in minutes—a crucial capability for agile market adaptation and the efficient fulfillment of fragmented consumer demands.

Environmental Regulations & Supply Chain Volatility

Global climate policies and supply chain volatility require a more resilient and sustainable manufacturing approach. Intelligent packaging machinery solutions mitigate the impact of new regulations, such as EU carbon tariffs, by reducing energy consumption by over 20%. Technologies like digital twins have become vital for enhancing supply chain response, allowing businesses to navigate disruptions that have historically led to significant financial losses.

Strategic Industry 4.0 Investment

The multi-trillion-dollar global Industry 4.0 market, currently growing at a 19% CAGR, reflects widespread adoption across major manufacturing hubs, particularly in the Asia-Pacific region. The transition toward custom integrated packaging lines is now a strategic imperative. Proven results, including substantial cost reductions and accelerated fault response, confirm that intelligent automation is the foundation for future excellence and market leadership.

Enhanced Workplace Safety & Ergonomics

Beyond regulatory compliance, modern consumers are increasingly prioritizing eco-friendly products. Advanced automatic packaging production lines utilize precision filling and "right-sized" packaging to minimize material waste and excess void space. By integrating technologies from automatic shrink wrap machines to robotic palletizers, these solutions lower both shipping costs and carbon footprints. This approach allows brands to meet growing environmental expectations while building a more responsible and appealing corporate identity.

Trends and Global Necessity

The global manufacturing landscape is undergoing a rapid transformation driven by Industry 4.0 technologies, where connectivity, automation, and intelligent systems define the future of production. For components like flat washers—used extensively across automotive, machinery, electronics, and industrial assembly—efficient and reliable packaging has become a strategic priority. The adoption of fully automated flat washer packing systems reflects not just technological advancement but a fundamental necessity for businesses seeking competitiveness and resilience in a dynamic market.

Rising Labor Costs

Increasing labor costs and a shrinking pool of skilled operators make traditional manual packing unsustainable for high-volume, precision-sensitive components. Automated flat washer packaging lines replace repetitive tasks with robotic handling and synchronized conveyors, reducing labor dependency while stabilizing operational costs and productivity.

Market Complexity and Demand Variability

Today’s supply chains demand flexibility and agility, with a broader range of product SKUs, customized orders, and rapid turnaround expectations. Traditional packing processes struggle to maintain accuracy and throughput under these conditions. Modern automated solutions enable quick changeovers and consistent output, allowing manufacturers to adapt rapidly to fluctuating demand without compromising quality.

Quality Assurance and Traceability Requirements

In industries requiring precise tolerances and full traceability, defects or miscounts can lead to costly rework or field failures. Integrated inspection solutions, such as dual vision systems and laser marking, ensure every part is verified before packing and permanently identified, supporting quality control and upstream/downstream traceability throughout the supply chain.

Sustainability and Supply Chain Resilience

Environmental regulations and supply chain volatility necessitate more efficient use of materials and energy. Automated systems minimize waste, optimize material usage, and reduce energy consumption, aligning with sustainability goals while enhancing operational resilience. Real-time data and connected systems also improve responsiveness to disruptions, enabling businesses to maintain continuity under changing conditions.

Strategic Investment in Smart Manufacturing

The global shift toward smart manufacturing and Industry 4.0 reflects a broader recognition that automation is no longer an optional upgrade but a core competitive strategy. Automated flat washer packaging lines provide real-time monitoring, predictive maintenance capabilities, and seamless integration with ERP/WMS systems, enabling manufacturers to achieve higher throughput, better quality consistency, and long-term operational stability.

Benefits of Automated Flat Washer Packaging Systems

Adopting an Industry 4.0–enabled Flat Washer Packaging System delivers measurable operational advantages by combining automation, data connectivity, and intelligent control.

Superior Product Protection & Quality Assurance

The automated flat washer packaging line is engineered to prevent common handling issues such as deformation, surface damage, and mixed batches. Integrated vision inspection systems perform real-time detection of missing, defective, or misaligned washers, ensuring only qualified products proceed to final packaging. This closed-loop quality control significantly reduces defect rates while maintaining consistent output standards for downstream logistics and end users.

Maximum Operational Efficiency Through Smart Automation

By leveraging high-speed conveyors, robotic handling, and synchronized control logic, the system dramatically increases packaging efficiency in high-volume washer production. Automation reduces manual intervention and stabilizes cycle times, while Industry 4.0–driven process coordination improves overall equipment effectiveness (OEE). Optimized material flow and precise counting mechanisms further enhance productivity and cost efficiency.

Flexible Configuration for Multiple Washer Specifications

Designed for SKU diversity, the flat washer packaging system features a modular architecture that supports fast changeovers between different washer sizes, quantities, and packaging formats. Intelligent parameter management enables rapid production adjustments with minimal downtime, allowing manufacturers to respond quickly to fluctuating order demands and customized packaging requirements.

Seamless End-to-End Packaging Integration

Joyda delivers a fully integrated packaging solution that connects feeding, storage, robotic loading, inspection, labeling, and stacking into a single automated workflow. From bulk washer intake to finished product unloading, each station operates under unified control, eliminating manual bottlenecks and ensuring a smooth, continuous production process across the entire packaging line.

Industry 4.0 Technology for Long-Term Scalability

The system incorporates real-time data acquisition, equipment status monitoring, and predictive maintenance capabilities, enabling proactive decision-making and reduced unplanned downtime. Digitalized production insights support continuous optimization and provide a scalable foundation for future line upgrades, ensuring long-term operational resilience in smart factory environments.

Global Standards Compliance & Proven System Integration Capability

All equipment is manufactured in accordance with internationally recognized standards, ensuring reliable operation across global markets. Backed by extensive experience in fastener, hardware, and industrial component packaging, Joyda delivers stable, production-ready systems supported by strong engineering integration capabilities and long-term technical support.

Why Choose Joyda?

Industry 4.0 Ready

AI-driven automation and intelligent control systems reduce labor dependency and operating costs while improving overall production efficiency and stability.

Turnkey Lines & Flexible Options

From complete turnkey packaging production lines to standalone machines, Joyda offers flexible solutions tailored to specific production requirements and capacity targets.

Fast Response & Professional Team

Experienced engineers and industry consultants deliver customized proposals within 48 hours, ensuring rapid project evaluation and decision-making.

Integrated Manufacturing

With in-house manufacturing and proprietary software teams, Joyda integrates mechanical engineering, automation control, and digital management into a unified system.

Proven Global Experience

Joyda packaging systems are successfully deployed across multiple industries, earning long-term trust from customers in global markets.

Everything You Need in One Location

From design and manufacturing to control and commissioning, Joyda provides everything in one location—one partner, one process, and one reliable result.

FAQ

The system is designed to handle a wide range of flat washer diameters, thicknesses, and materials. Through adjustable feeding mechanisms and programmable robotic handling, the line can be customized to accommodate different washer specifications without compromising accuracy.

Counting accuracy is achieved through a combination of controlled feeding, robotic placement, and integrated vision inspection systems. This multi-layer verification approach minimizes counting errors and ensures consistent packaging quantities.

Yes. The fully automated design, including double-speed chain conveyors and robotic handling, enables stable high-speed operation suitable for large-scale industrial production with minimal downtime.

The line integrates multiple vision inspection systems to perform real-time quality checks. Defective or non-conforming washers can be detected and removed automatically before final packaging.

Laser marking can be integrated as part of the line to create permanent, traceable marks on products or packaging. The configuration can be customized based on traceability and branding requirements.

Industry 4.0 integration enables real-time production monitoring, data collection, and predictive maintenance. This allows operators to identify issues early, optimize performance, and reduce unexpected downtime.

Yes. Joyda’s in-house software supports ERP integration, enabling seamless data exchange for production tracking, labeling information, and quality records.

The modular design allows for easy upgrades and reconfiguration. New washer sizes, packaging formats, or labeling requirements can be implemented with minimal structural changes.

By replacing manual feeding, counting, inspection, and labeling processes, the automated line significantly reduces labor dependency while improving consistency and workplace safety.

Joyda offers end-to-end support, including system commissioning, operator training, remote diagnostics, and responsive technical service to ensure long-term stable operation.