Industry 4.0 Book Packing Line for Accurate, Secure, and Traceable Packaging

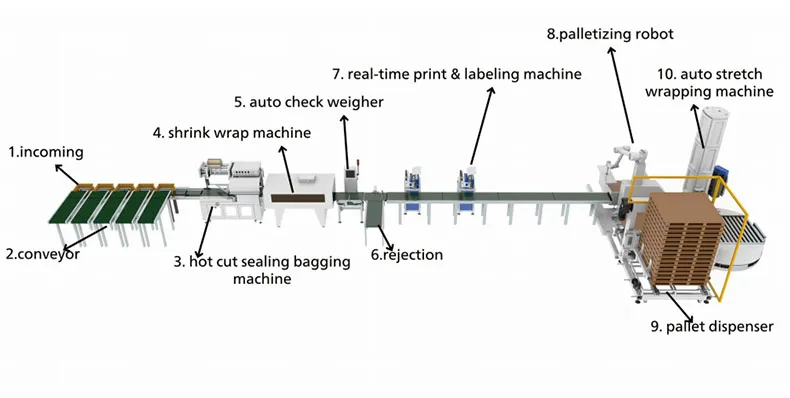

Transform your facility with a fully automatic packaging production line designed specifically for the book industry, seamlessly integrating conveying, hot-cut sealing, shrink wrapping, check weighing, labeling, and robot palletizing. Optimized for Industry 4.0 environments, these intelligent end-of-line packaging solutions enhance your packaging precision, minimize manual handling, and ensure stable, high-throughput book fulfillment to keep your production moving forward.

What is Books Packaging System?

Our Books Packaging System is a fully automated, Industry 4.0-ready solution that seamlessly integrates every stage of the automatic packaging production line through intelligent control and advanced robotics. By combining mechanical engineering with smart software, this system creates a unified workflow designed to handle high-volume book fulfillment with maximum precision and minimal manual intervention.

The process begins with automated incoming and conveying, where books are systematically received and transferred for efficient batch stacking. The products then move through bagging or shrink wrapping modules to ensure durable, protective packaging. To maintain strict quality standards, an integrated auto check weigher and rejection system monitor every unit, while high-speed labeling systems enable real-time tracking and precise product identification.

To complete these end-of-line packaging solutions, a robot palletizing system efficiently stacks the finished books onto pallets provided by an automatic dispenser. Finally, an auto stretch wrapping machine secures the entire load for safe storage and transport. By integrating real-time data and smart sensors, this turnkey project enhances operational efficiency and ensures consistent, high-quality output for any modern packaging production line.

Books Line Solution Components

Introduction

1.Incoming

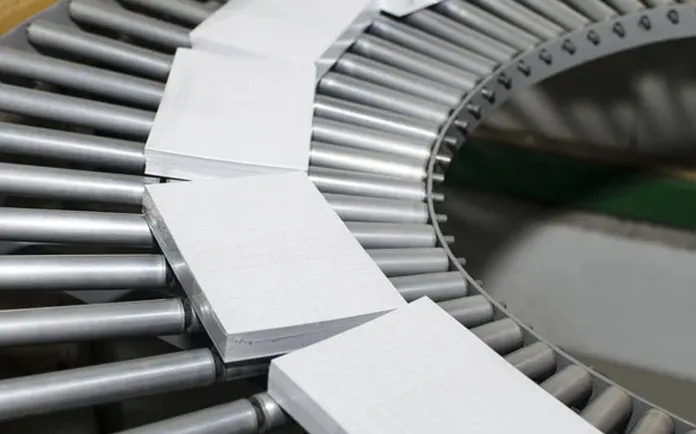

2. Conveyor: convey the books (1.2) Stacked books in batches

3. Hot cut sealing bagging machine:

A device that uses heat to melt and join layers of thermoplastic material,

simultaneously sealing them and cutting the excess plastic to create a finished

bag or package.

4. Shrink wrap machine:

A device that uses heatto melt and join layers of thermoplastic material,

simultaneously sealing them and cutting the excess plastic to create a finished

bag or package.

5. Auto check weigher:

A device that determines the mass of an object without requiring direct human

intervention during the weighing process.

6.Rejection

7.Real-time print&labeling machine

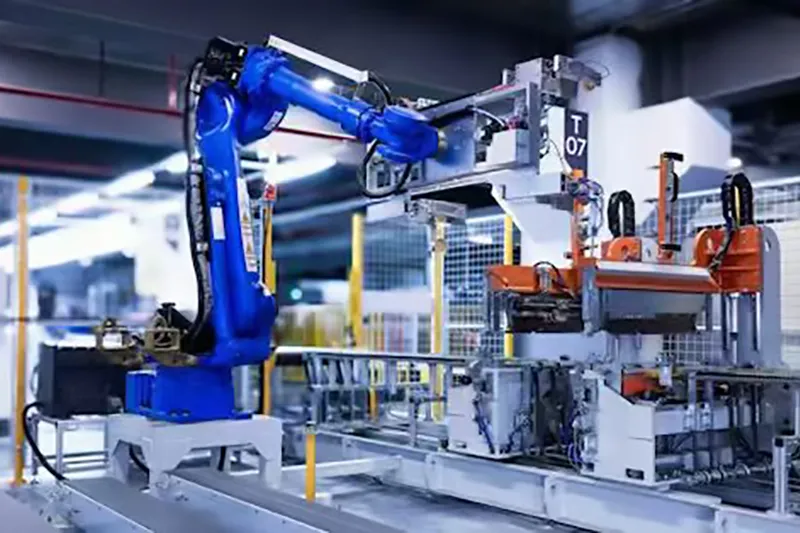

8. Palletizing robot:

An automated system that uses robotic arms to pick and place products into

shipping cases.

9.Pallet dispenser

10.Auto stretch wrapping machine:

An automated robotic system used to stack products onto pallets, typically at the

end of a production line.

Trends and Global Necessity

The global manufacturing landscape is rapidly evolving toward the Intelligent Revolution, commonly known as Industry 4.0. Driven by Cyber-Physical Systems (CPS), IoT, and AI, this shift has transitioned from a technological upgrade to a fundamental necessity for businesses to remain competitive. The rising demand for advanced packaging automation solutions, particularly within the automatic packaging machine sector, is underscored by several critical global trends.

Rising Labor Costs

Unsustainable increases in manufacturing labor costs—averaging 5% to 8% annually—serve as a primary driver for automation. By replacing manual, repetitive tasks with efficient packaging machinery, companies can significantly reduce overheads while ensuring long-term cost-effectiveness. This strategic investment in automatic packaging lines provides a proven ROI by addressing one of the most volatile and significant operational expenses in modern business.

Fragmented Customer Demands & E-commerce

The explosive growth of e-commerce has led to increased SKU diversification and a rise in smaller, customized orders. Traditional, inflexible production lines with 4 to 8-hour changeovers are increasingly obsolete. Modern book packaging machine systems and cartoning machine solutions are engineered for this new reality. Featuring modular designs and intelligent software, they enable rapid changeovers in minutes—a crucial capability for agile market adaptation and the efficient fulfillment of fragmented consumer demands.

Environmental Regulations & Supply Chain Volatility

Global climate policies and supply chain volatility require a more resilient and sustainable manufacturing approach. Intelligent packaging machinery solutions mitigate the impact of new regulations, such as EU carbon tariffs, by reducing energy consumption by over 20%. Technologies like digital twins have become vital for enhancing supply chain response, allowing businesses to navigate disruptions that have historically led to significant financial losses.

Strategic Industry 4.0 Investment

The multi-trillion-dollar global Industry 4.0 market, currently growing at a 19% CAGR, reflects widespread adoption across major manufacturing hubs, particularly in the Asia-Pacific region. The transition toward custom integrated packaging lines is now a strategic imperative. Proven results, including substantial cost reductions and accelerated fault response, confirm that intelligent automation is the foundation for future excellence and market leadership.

Enhanced Workplace Safety & Ergonomics

Beyond regulatory compliance, modern consumers are increasingly prioritizing eco-friendly products. Advanced automatic packaging production lines utilize precision filling and "right-sized" packaging to minimize material waste and excess void space. By integrating technologies from automatic shrink wrap machines to robotic palletizers, these solutions lower both shipping costs and carbon footprints. This approach allows brands to meet growing environmental expectations while building a more responsible and appealing corporate identity.

Benefits of Books Packaging Systems

In the evolving publishing and logistics landscape, intelligent book packaging machine systems are no longer just an operational upgrade but a strategic imperative. By addressing core challenges from production to delivery, these advanced solutions deliver multifaceted benefits, ensuring product integrity, operational efficiency, and enhanced customer satisfaction.

Superior Book Protection

The automatic shrink wrap machine and cartoning machine are engineered to prevent common shipping damages, such as dents and corner bumps. When integrated with a high-precision visual inspection system, the equipment performs real-time scanning to detect and reject defective products before the final packaging stage. This proactive quality control significantly lowers product damage rates and safeguards brand reputation through consistent, pristine delivery.

Maximum Operational Efficiency

Our packaging machinery boosts overall operational efficiency by over 40%, allowing facilities to handle high order volumes with precision. These automated packaging solutions reduce reliance on manual labor, leading to a 30% or more reduction in labor costs. Furthermore, precision packing algorithms optimize material usage, improving raw material utilization rates from 82% to 93%, which directly enhances the bottom line.

Flexible & Rapid Production Changeovers

To meet the demands of SKU diversification and e-commerce growth, Joyda packaging machine systems feature a modular design that facilitates rapid changeovers in as little as 15 minutes. This inherent flexibility allows an automatic packaging line to adapt quickly to different book sizes and packaging specifications, ensuring maximum uptime and a distinct competitive edge in agile manufacturing.

Seamless End-to-End Automation

Joyda provides a complete, end-to-end packaging line that eliminates manual bottlenecks. Our systems seamlessly integrate the cartoning machine, case erector, check weigher, robotic palletizer, and automatic strapping machine. This integration ensures a smooth, continuous workflow from the primary packaging floor directly to the shipping dock, providing a true turnkey project experience.

Cutting-Edge Technology for Future-Proofing

We leverage advanced Industry 4.0 technologies, including digital twin simulations and real-time data analysis, to create smart, responsive production environments. These solutions provide the necessary tools to optimize production schedules, predict maintenance needs, and gain actionable insights, ensuring that a packaging production line remains resilient and competitive for years to come.

Global Compliance & Trusted Partnerships

All machines are manufactured to meet rigorous global standards, including ISO, CE, and UKCA, ensuring reliable operations worldwide. Beyond the book industry, Joyda is recognized as a professional supplier of perfume production lines and a partner to beverage packaging machine manufacturers. Our extensive partnerships across Asia, Europe, and Mexico reflect our reliability as a premier provider of custom integrated packaging lines.

Why Choose Joyda?

Industry 4.0 Ready

AI-driven automation reduces labor and cost, boosting overall efficiency.

Turnkey Lines & Flexible Options

One-stop packaging lines or single machines — choose what fits your needs.

Fast Response & Professional Team

48-hour proposal delivery by experienced engineers and expert consultants.

Integrated Manufacturing & Software Control

Own factory + two software companies — seamless integration of mechanical production and automation control.

Proven Global Experience

Applied in multiple industries — packaging solutions trusted worldwide.

Everything You Need in One Location

Design, build, and control — one partner, one process, one result.

FAQ

Loose padding or weak boxes during shipping. Add firm cushions and use strong cartons to protect corners, like in our systems that hold books tight.

Use better adhesives for humid air. Our labelers apply them even at 70m/min, avoiding slips seen in Quora shipping complaints.

Online sales boom, but damage rises. Reddit notes returns from poor padding; our systems cut that by 20%.

Yes, with sealed parts. Southeast Asia searches mention mold from damp; our designs keep labels dry and books safe.

Weekly checks on padders. Quora says ignoring buildup causes stops; our alerts catch issues before they slow output.

Starts at $12,000, up with speed. PAA asks for ROI; ours return in 12-24 months via fewer dents.

Our flexible ones switch quick. Reddit publishing posts complain of rigid tools; we handle thin novels to thick texts.

Waste rules like PPWR. SERP shows compliance demands; our systems use low-waste padding to meet them.

Transit delays raise damage. Forums like Quora highlight gaps; our strong seals and quick parts help.

High shipping costs cause shortcuts. Regional data notes affordability; our durable systems cut rework by 25%.