Industry 4.0 Carton Packing Line with End-to-End Automation

A high-performance automatic packaging production line integrating an automatic case erector, conveying, sealing, box turning, precision corner taping, and labeling. Configured for Industry 4.0 smart factories, this synchronized Carton Packaging Line ensures stable, high-throughput output and consistent packaging quality with minimal manual intervention, providing a robust solution for modern end-of-line packaging solutions.

What is Automatic Carton Packaging System?

The Automatic Carton Packaging System is a fully integrated, end-to-end automatic packaging production line engineered to maximize operational efficiency through advanced automation. By combining high-performance packaging machinery with robotics and Industry 4.0 connectivity, this system ensures high-speed precision while significantly minimizing the need for manual intervention across the entire workflow.

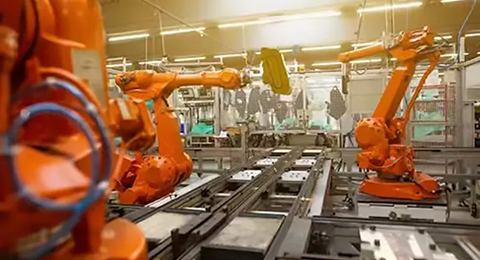

From the initial stage of the automatic case erector to automated case packing, sealing, and robotic palletizing, the system streamlines the complete secondary packaging operation. A high-precision robotic case packer ensures accurate product placement, while the automatic sealing mechanism—often incorporating corner taping—guarantees secure, tamper-proof cartons. The final phase integrates robotic palletizing and automated stretch wrapping, providing a unified and reliable solution for transport-ready goods.

The implementation of this automated system effectively reduces labor costs, eliminates human error, and optimizes material usage. These end-of-line packaging solutions lead to faster production cycles and consistent output quality, providing a scalable and future-proof foundation for modern Carton Packaging Lines seeking maximum throughput and operational excellence.

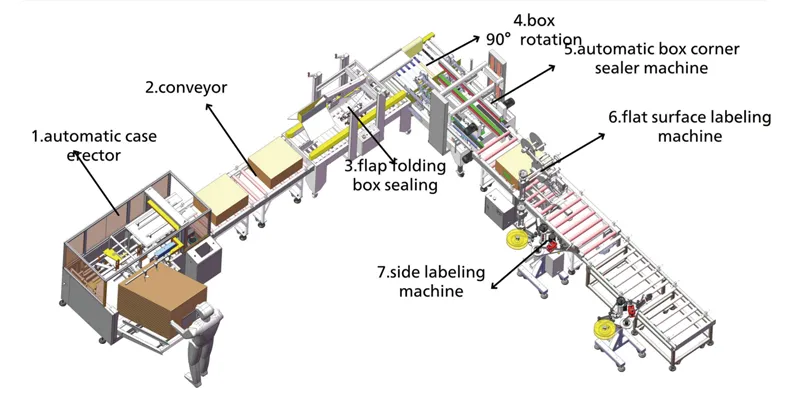

Automatic Carton Line Solution Components

Introduction

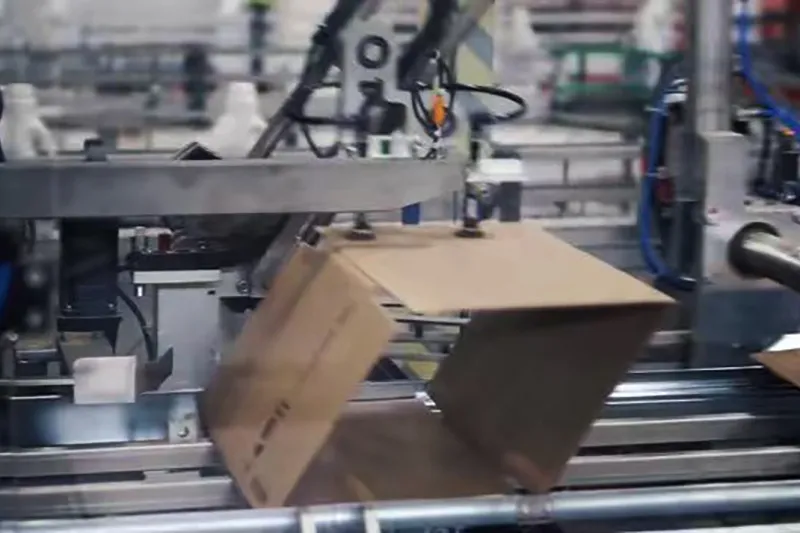

1.Automatic case erector:

It essentially transforms flat box blanks into usable containers, often using tape

or glue to seal the bottom .

2.Conveyor:

convey the product.

3.Flap folding sealing machine:

Automate the entire carton sealing process, from carton erection to flap foldingand sealing,requiring minimal manual intervention.

4.90°turning box

5.Automatic box corner sealer:

A device that automatically applies tape to the corners of boxes, securing themfor shipping or storage.

6.Flat surface labeling machine:

Machine for attaching labels to the surface of the product.

7.Side labeling machine:

The machine for attaching labels to the side of the carton.

Trends and Global Necessity

The manufacturing landscape is rapidly evolving into the Intelligent Revolution, known as Industry 4.0. Driven by Cyber-Physical Systems (CPS), IoT, and AI, this shift has become a fundamental necessity for businesses to thrive globally. The imperative for advanced automation, especially within the automated packaging machine sector, is underscored by several critical trends shaping the future of fully integrated automatic packaging production lines.

Rising Labor Costs

Unsustainable increases in global manufacturing labor costs—averaging 5% to 8% annually—are a primary driver for full-scale automation. By replacing manual, repetitive tasks with a high-efficiency automatic packaging line, companies can directly reduce overheads and ensure long-term economic viability. For large-scale facilities, these packaging machinery solutions provide a proven ROI by eliminating the financial volatility associated with manual labor in the Carton Packaging Lines sector.

Fragmented Customer Demands & E-commerce

The explosive growth of e-commerce has led to increased SKU diversification and a rise in smaller, customized orders. Traditional, inflexible production lines are becoming obsolete. Modern automatic packaging production lines are built for this new reality, featuring modular designs from leading case erector manufacturers that enable rapid changeovers in minutes—crucial for agile market adaptation and the efficient fulfillment of fragmented packaging demands.

Environmental Regulations & Supply Chain Volatility

Global climate policies and supply chain disruptions demand a more resilient and sustainable manufacturing approach. Intelligent packaging machinery solutions mitigate the impact of new regulations, such as carbon tariffs, by reducing energy consumption by over 20%. Technologies like digital twins are now vital for enhancing supply chain response, allowing businesses to navigate disruptions while optimizing material usage across their end-of-line packaging solutions.

Strategic Industry 4.0 Investment

The multi-trillion-dollar global Industry 4.0 market reflects widespread adoption across major manufacturing hubs. The transition toward custom integrated packaging lines is a strategic imperative for achieving operational excellence. Proven results confirm that intelligent automation is the foundation for maintaining a global competitive edge and ensuring the long-term resilience of a fully synchronized automatic packaging production line.

Enhanced Workplace Safety & Ergonomics

Beyond regulations, manufacturers are focused on reducing workplace injuries associated with heavy lifting and repetitive manual packing. Advanced automatic packaging production lines utilize precision robotics to minimize material waste and human strain. By integrating high-performance robotic palletizers, manufacturers meet safety standards while building a more responsible brand image through optimized, future-proof packaging operations.

Benefits of Carton Packing Production Line

Adopting an automated Carton Packing Production Line offers numerous benefits that drive efficiency, reduce costs, and improve product quality. Here are the key advantages:

Increased Efficiency

Automation accelerates the entire packaging process, reducing cycle times and maximizing throughput, ensuring faster production with fewer delays.

Cost Savings

By minimizing the need for manual labor and reducing errors, our system helps cut operational costs while optimizing material usage, making it a highly cost-effective solution.

Consistent, High-Quality Packaging

The automated system ensures uniformity and precision in every package, eliminating human error and ensuring consistent packaging quality across all products.

Reduced Labor Dependency

With robotics handling repetitive tasks, your workforce can focus on more strategic activities, reducing the risk of injuries and increasing overall workplace safety.

Scalability and Flexibility

Our system is designed to adapt as your business grows, offering easy scalability to meet increasing production demands or adjust to new packaging specifications.

Sustainability

The system reduces material waste by optimizing carton cutting and packing, contributing to more sustainable production practices while lowering environmental impact.

Why Choose Joyda?

Industry 4.0 Integration

Our systems incorporate the latest Industry 4.0 technologies, enabling real-time monitoring, predictive maintenance, and seamless integration with your existing production lines, ensuring smarter and more efficient packaging processes.

Tailored Automation Solutions

We don’t believe in one-size-fits-all. Our Carton Packing Production Line is customizable to meet your specific production needs, offering flexibility to handle a wide range of products, sizes, and packaging requirements.

Proven Expertise Across Industries

With extensive experience in sectors like automotive, electronics, food, and medical, we understand the unique challenges of each industry and provide tailored solutions that improve efficiency and product integrity.

In-House Software Development

We design and develop our own ERP-integrated software, giving you full control over the entire packaging process. Our proprietary software ensures precise operation, real-time data tracking, and smooth system integration.

Commitment to Innovation and Quality

We invest heavily in R&D to stay ahead of industry trends and continuously improve our solutions. Our focus on quality control and cutting-edge technology guarantees reliable, high-performance packaging systems that give you a competitive edge.

End-to-End Customer Support

From consultation and installation to ongoing service, we offer comprehensive support to ensure your system runs smoothly. Our team provides training, troubleshooting, and rapid assistance to keep your production line running at peak performance.

FAQ

The system automates every step of the packaging process, from carton forming to sealing and palletizing. This reduces manual handling, accelerates production speeds, and minimizes downtime, ultimately improving overall efficiency.

Yes, our system is highly flexible and can be customized to handle various carton sizes and packaging configurations, making it suitable for a wide range of products.

Automation reduces labor costs, minimizes human error, and ensures consistent, high-quality packaging. It also speeds up production and lowers material waste, delivering a high return on investment over time.

Absolutely. Our automatic carton packing system is designed to be scalable, allowing you to easily expand or modify the system as your production volume increases or as packaging requirements change.

The system uses advanced robotics and sensors to handle products with precision, ensuring each package is securely sealed and correctly packed, minimizing defects and ensuring a high standard of quality.

The system is designed for easy maintenance, with automated diagnostics and predictive maintenance features to detect issues before they cause downtime. We also provide training and full technical support for ongoing maintenance needs.

Yes, our system is designed to integrate seamlessly with your existing ERP and production management systems, enabling real-time data tracking and process optimization.

Our system is designed to be energy-efficient and reduce material waste through precise packing. Additionally, it helps streamline resource usage, contributing to more sustainable packaging practices.

Challenges can include differences in local regulations, supply chain logistics, and environmental factors. However, we offer full support to ensure that the system is tailored to meet local standards and adapt to regional requirements.

Installation time varies based on the complexity of the system and specific client needs. Typically, we ensure a smooth, efficient setup process that minimizes disruption to your existing operations.