Industry 4.0 Juice Bottle Packing Line with Robotics & Inspection

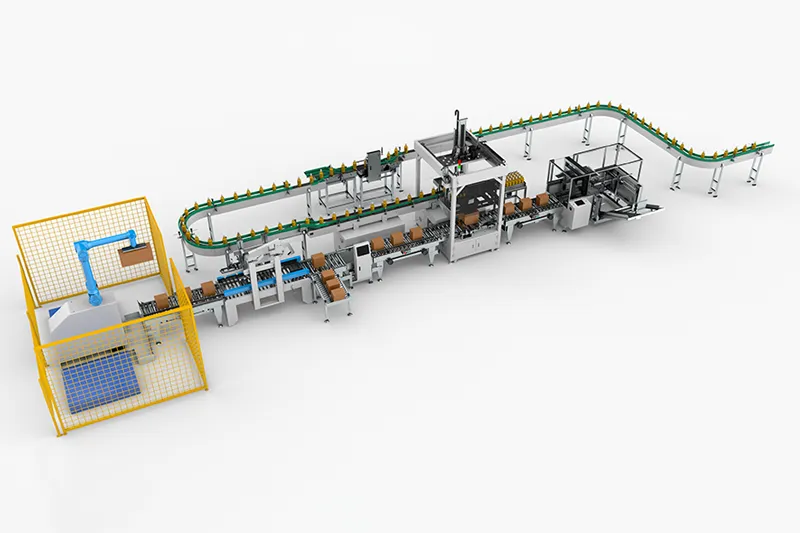

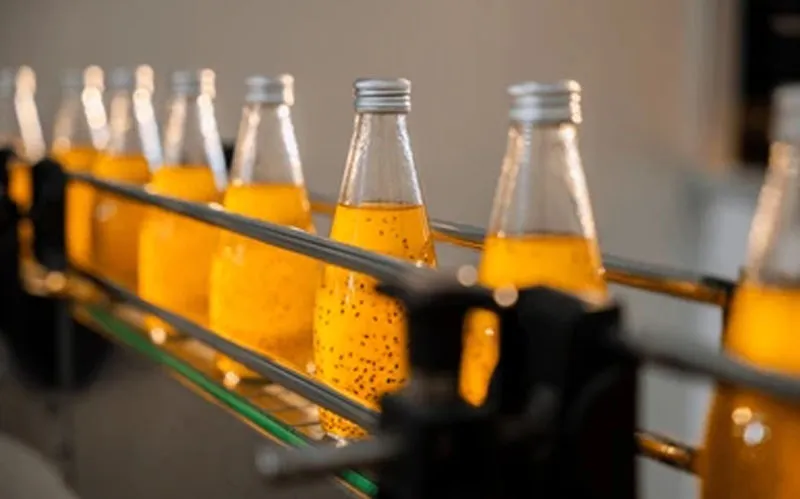

A complete Industry 4.0 Juice Packaging Line enabling continuous conveying, precise case packing, intelligent rejection, and robotic palletizing. This automatic packaging production line—also highly effective as a mineral water bottle packaging machine solution—enhances throughput and reduces labor dependency across large-scale beverage operations, ensuring stable and efficient bottle packaging line performance.

What is Juice bottle packing production line?

The Juice Bottle Packing Production Line is a fully integrated, automatic packaging production line that synchronizes every stage of the secondary packaging process—from conveying and case packing to final palletizing. Engineered with Industry 4.0 smart manufacturing principles, this system combines digital control and real-time monitoring to achieve continuous, high-efficiency production. These Bottle packaging line solutions are designed to handle high-volume demands while ensuring the hygienic and structural integrity of the final product.

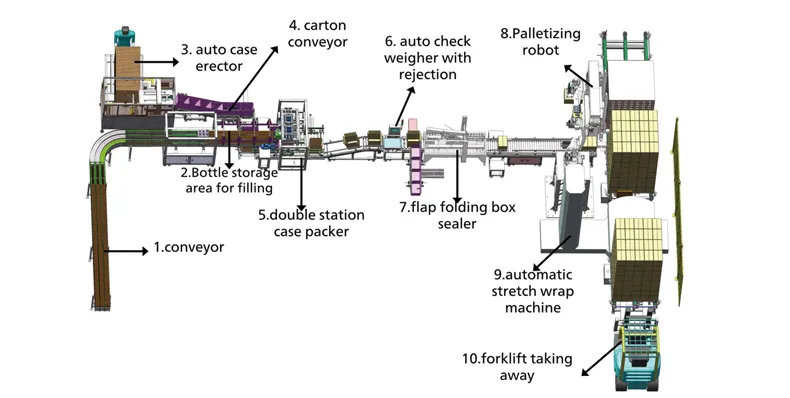

The workflow begins with a high-speed conveyor system that transports bottles to the designated accumulation area. Simultaneously, an automatic case erector machine forms flat cartons, which are then transferred via carton conveyor to a precision double-station case packer. At this stage, the filled bottles are automatically and accurately placed into the formed boxes. To maintain strict quality standards, an integrated check weigher with an automated rejection system verifies the weight of each carton before it proceeds to the flap-folding box sealer.

The final phase of this end-of-line packaging solution involves a high-performance robotic palletizer that systematically stacks the finished cartons onto pallets. An automatic stretch wrap machine then secures the load for stable transport, allowing for efficient forklift transfer to storage or shipment. By implementing this intelligent Juice Packaging Line, manufacturers can significantly enhance productivity, maintain consistent packaging quality, and reduce long-term labor and operational costs.

Juice Bottle Line Solution Components

Introduction

1.Conveyor:

Convey the bottle

2.Bottle storage area for filling

3.Automatic box erector machine:

It essentially transforms flat box blanks into usable containers, often using tape

or glue to seal the bottom .

4.Carton conveyor:

Convey the carton.

5.Double station case packer:

The machine for placing bottles into the pre-packaged boxes.

6.Checkweigher with Rejection:

A device that can determine the mass of an object during weighing and that

automatically eliminates objects whose weight does not meet the requirements.

7.Flap folding box sealer:

Automate the entire carton sealing process, from carton erection to flap foldingand sealing,requiring minimal manual intervention.

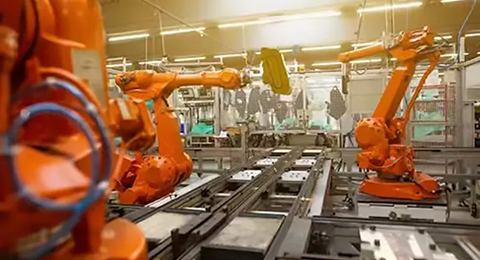

8.Palletizing robot:

An automated robotic system used to stack products onto pallets, typically at theend of a production line.

9.Automatic stretch wrap machine:

A piece of equipment used to apply stretch film to a palletized load, securing itfor storage and shipping.

10.Forklift take away

Trends and Global Necessity

The manufacturing landscape is rapidly evolving into the Intelligent Revolution, known as Industry 4.0. Driven by Cyber-Physical Systems (CPS), IoT, and AI, this shift has become a fundamental necessity for businesses to thrive globally. The imperative for advanced automation, especially within the automated packaging machine sector, is underscored by several critical trends shaping the future of Juice Packaging Lines and bottle packaging lines.

Rising Labor Costs

Unsustainable increases in global manufacturing labor costs—averaging 5% to 8% annually—are a primary driver for automation. By replacing manual, repetitive tasks with efficient packaging machinery, companies can directly reduce overheads and ensure long-term economic viability. This strategic investment in an automatic packaging line provides a proven ROI by addressing one of the most volatile and significant operational expenses in the beverage industry.

Fragmented Customer Demands & E-commerce

The explosive growth of e-commerce has led to increased SKU diversification and a rise in smaller, customized orders, such as multi-packs or various bottle sizes. Traditional, inflexible production lines are becoming obsolete. Modern Juice Packaging Lines and mineral water bottle packaging machine systems are built for this new reality, featuring modular designs and advanced software that enable rapid changeovers in minutes—crucial for agile market adaptation and the efficient fulfillment of fragmented demands.

Environmental Regulations & Supply Chain Volatility

Global climate policies and supply chain disruptions demand a more resilient and sustainable manufacturing approach. Intelligent packaging machinery solutions mitigate the impact of new regulations, such as carbon tariffs, by reducing energy consumption by over 20%. Technologies like digital twins are now vital for enhancing supply chain response and resilience, allowing businesses to navigate disruptions that have historically caused significant financial losses in large-scale beverage operations.

Strategic Industry 4.0 Investment

The multi-trillion-dollar global Industry 4.0 market, growing at nearly 19% CAGR, reflects widespread adoption across major manufacturing hubs. The transition toward custom integrated packaging lines is now a strategic imperative for achieving operational excellence. Proven results confirm that intelligent automation is the foundation for maintaining a global competitive edge and ensuring the long-term resilience of an automatic packaging production line.

Enhanced Workplace Safety & Ergonomics

Beyond regulations, consumers are increasingly demanding eco-friendly products and "right-sized" packaging. Advanced automatic packaging production lines utilize precision technology to minimize material waste, such as shrink film and cardboard. By integrating solutions like robotic palletizers, manufacturers can lower both shipping costs and carbon footprints, meeting growing customer expectations while building a more responsible, appealing brand image.

Benefits of Juice Bottle Packing Production line

In the evolving publishing and logistics landscape, intelligent book packaging machine systems are no longer just an operational upgrade but a strategic imperative. By addressing core challenges from production to delivery, these advanced solutions deliver multifaceted benefits, ensuring product integrity, operational efficiency, and enhanced customer satisfaction.

Seamless Integration with Industry 4.0

Our juice bottle packing line integrates intelligent PLC control, ERP connectivity, and real-time data analytics, helping beverage factories accelerate digital transformation. Systems are fully compatible with MES, enabling production transparency, traceability, and decision-making based on live operational data.

Flexible Bottle and Packaging Format Compatibility

The line is adaptable to various bottle materials (PET, glass, HDPE), cap styles, shrink bundles, trays, or wrap-around cartons. This flexibility reduces SKU changeover complexity and helps beverage companies respond quickly to seasonal products, promotions, and market shifts without investing in new production lines.

High Output Efficiency with Automated Reliability

With automated conveying, filling-to-final palletizing workflow, and robotic handling, the line significantly reduces manual labor. The design ensures high operational uptime, stable speed performance, and strict synchronization between each module for consistent output quality.

Smart Quality Control and Hygiene-Driven Design

Vision-based inspection verifies filling level, label placement, cap sealing, and barcode correctness. Contactless sensors and food-grade material design prevent contamination, supporting beverage GMP compliance and ensuring that every bottle meets export and retail standards.

Low Operating Cost with Predictive Maintenance

AI-enabled monitoring detects vibration, abnormal motor consumption, or system drift before breakdown occurs. This predictive maintenance reduces downtime, stabilizes output scheduling, and extends equipment lifespan, resulting in lower long-term operational cost.

Scalable and Future-Proof Architecture

The system supports modular expansion, allowing customers to add robotic depalletizers, high-speed shrink wrappers, traceability modules, or automated pallet warehouses later. This ensures long-term scalability as production demand grows or product lines diversify.

Why Choose Joyda?

Industry 4.0 Ready

We lead with intelligent automation. Our in-house software integrates with your ERP, leveraging AI and IoT for seamless data flow and autonomous decision-making. This means flexible production, real-time optimization, and significant cost control, cutting changeover times to 15 minutes and energy use by 22%.

Packaging & Tape Application Experts

Specializing in tape applicators and full packaging systems, we solve common line issues like jams and slow seals. Our strength is blending robust hardware with smart software for smooth, hitch-free operations.

Proven Cost & Efficiency Gains

Our automation reduces direct labor costs by 30%. With MES-driven digital control, we cut fault response time to under 30 seconds, boosting overall efficiency by over 40%. Clients see product damage drop from 3% to 0.2% and unplanned downtime cut by 75%.

Flexible & Rapid Changeover

Our modular design allows packaging specification changes in just 15 minutes, down from hours. We adapt to diverse needs, handling various product sizes and bag shapes, enabling quick product type changes and dynamic formula management.

Robust In-House Manufacturing & Testing

Our 30,000 sqm Dongguan factory produces all equipment with stringent QC. We conduct real-world tests to ensure stability, preventing unexpected stops and ensuring your lines run steadily.

Global Compliance & Trusted Partnerships

Our machines meet global standards (ISO 9001, CE, UKCA, EAC, AS/NZS, NOM), ensuring smooth worldwide operations. Our long-term partnerships with manufacturers across Asia, Europe, and Mexico validate Joyda's reliability and value.

FAQ

We provide engineering assessment, layout simulation, and digital twin planning to ensure the line fits your existing workflow, utilities, and automation level. Whether upgrading from a semi-manual process or integrating into a fully automated environment, our engineering team will adjust configuration and flow direction to match your space and operational requirements.

Yes. The system is engineered for fast tool-less adjustment and software-based format switching. This allows operators to change between sizes, cap types, label formats, or packaging specifications with minimal downtime, making it suitable for high-mix, mid-volume production scenarios.

The line supports from semi-automated upgrades to full Industry 4.0 intelligent packing lines, including robotic palletizing, AGV logistics, and centralized control software. The final automation scope depends on your ROI target, workforce structure, production capacity, and long-term expansion strategy.

All modules follow beverage-grade hygiene standards with stainless-steel construction, washable enclosures, closed-loop conveyors, and optional HEPA modules. Automated inspections ensure sealing accuracy, labeling consistency, and product traceability, enabling compliance with export and supermarket audit requirements.

Timelines vary depending on customization level and factory size. Typically, standard-configuration lines require several weeks for installation, calibration, operator training, and trial production. We ensure you can move smoothly into mass production with stable output and certified operational staff.

We provide remote diagnostics, software updates, spare parts supply, and scheduled on-site service depending on your service package. With Industry 4.0 monitoring, many performance issues can be detected and resolved before they impact production, ensuring stable operation with minimized downtime and lower long-term maintenance workload.

Yes. The system supports open industrial communication protocols such as OPC-UA, EtherCAT, Modbus, and Profinet, enabling seamless interoperability with current fillers, blow molders, labeling machines, or warehouse systems. Our integration team evaluates your existing setup and ensures a unified operational command through centralized control software.

The automated line optimizes motion paths, conveyor logic, servo efficiency, and airflow usage in shrink packaging, reducing electricity and consumable waste. Combined with predictive maintenance and reduced manual labor dependence, most beverage factories achieve cost reductions and increased productivity within the first operational year.

With proper maintenance and software updates, the system is designed to operate reliably for many years. Components are industrial-grade, globally sourced, and replaceable. The modular hardware and scalable software architecture allow the system to remain relevant even as production volumes grow or product requirements evolve.

Yes. Operator and maintenance training are included in commissioning. The interface is designed with intuitive controls, recipe-based setup, and visual guidance, making it easy for operators with minimal automation background to manage. Training ensures your team can perform daily operation, troubleshooting, safety checks, and routine adjustments confidently.