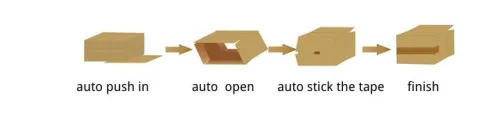

Equipment Introduction:

The Plc+hmi System Automates Packaging Processes Including Box Suction, Forming, Bottom Folding, And Sealing in Single-Cycle Operation. Features Unmanned Automation with Time/Labor Efficiency,case Erector with 80-100 (800-1000mm)carton Buffer Capacity.Applicable to Food, Beverage, Stationery, Hardware, Consumer Goods, And Chemical Industries.

Foreign trade parameters:

| Port: | Shenzhen, China |

| Production Capacity: | 5 Set/Sets Per Month |

| Payment Terms: | L/C, T/T, D/P, Western Union, Paypal, Money Gram |

| Certification: | ISO9001, ISO, CE |

| Application: | Toy, Apparel, Gifts & Arts, Food |

| Driven Type: | Pneumatic |

| After-Sales Service Provided: | Engineers Available to Service Machinery Overseas |

| Type: | Automatic Carton Making Machine |

| Automatic Grade: | Automatic |

Technical Parameters:

| Packing speed: | 12 boxes/min |

| The size range of the box: | length 130 – 320mm, width 80 – 200mm, height 100 – 400mm. |

| Voltage: | 220V 50/60Hz |

| Power: | 240W |

| Tape size: | 48/60/75mm |

| Work surface height: | 620 – 670 mm |

| Machine size: | L2100*W2100*H1450mm |

Features:

● Tape guard door enables quick-access tape replacement.

● Upgraded flap folding ensures smooth, stable, and durable carton forming.

● Heavy-duty high-friction conveyor belt ensures stable transportation.

Finished product image: