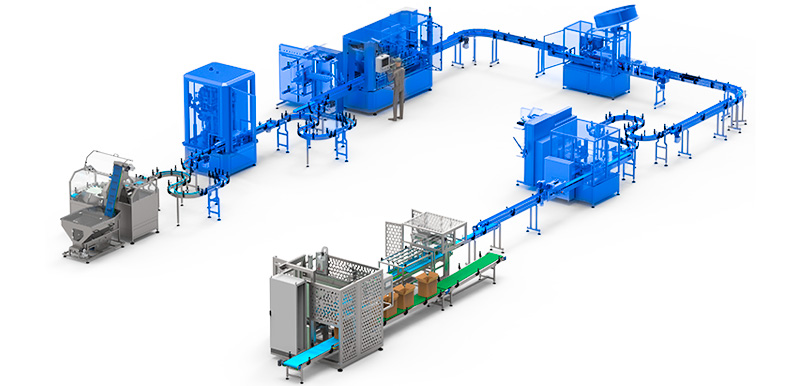

End-of-line automation, encompassing case erecting, sealing, and palletizing, is the ultimate solution for transforming labor-intensive packaging into a highly efficient, consistent, and cost-effective process. By integrating advanced machinery like case erectors, case sealers, robotic palletizers, and automatic stretch wrappers, businesses can eliminate physical strain, boost throughput, ensure product integrity, and achieve significant ROI.

Are your end-of-line packaging tasks a bottleneck? Manual case assembly, sealing, and palletizing are not only time-consuming but also physically demanding, leading to worker fatigue, injuries, and inconsistent output. These labor-intensive processes can significantly slow down your entire operation, impacting shipping schedules and increasing operational costs. This guide will walk you through the essential components of end-of-line automation—case erecting, sealing, and palletizing—demonstrating how a fully integrated system from Joyda Totalpack can revolutionize your final packaging stages, ensuring efficiency, consistency, and a rapid return on investment.

Table of Contents

- Automating Case Preparation: The Case Erector

- Securing the Product: The Case Sealer

- The Powerhouse: Robotic Palletizing

- Ready for Shipment: TheAutomatic Stretch Wrapper

- Cumulative ROI of End-of-Line Automation

1. Automating Case Preparation: The Case Erector

Tired of slow, manual box assembly? The case erector is your solution for fast, consistent case preparation.

The Case Erector automates the process of taking flat cardboard blanks and forming them into open, bottom-sealed boxes, ready for product filling. This machine eliminates manual labor, ensures uniform case dimensions, and significantly increases the speed and efficiency of the initial packaging stage.

1.1 From Flat Blanks to Sealed-Bottom Boxes

The journey of end-of-line automation begins with the Case Erector. This essential machine takes flat, pre-cut cardboard blanks (often called “knock-down flats”) and automatically erects them into three-dimensional boxes. The process involves precise folding along pre-scored lines and then securely sealing the bottom flaps, typically using hot-melt adhesive or adhesive tape. The result is a perfectly formed, open-top box, ready to receive products from upstream filling or packing machines. For example, in a beverage bottling plant, the case erector rapidly prepares cartons to hold multiple bottles, ensuring each carton is consistently square and robust. Joyda Totalpack’s case erectors are designed for high-speed operation and consistent output, providing a reliable foundation for the entire end-of-line process.

| Case Erector Function | Benefit |

| Automatic Folding | Eliminates manual assembly, boosts speed. |

| Bottom Sealing | Ensures structural integrity for filling. |

| Uniform Output | Critical for seamless downstream automation. |

| High Speed | Matches throughput of high-volume lines. |

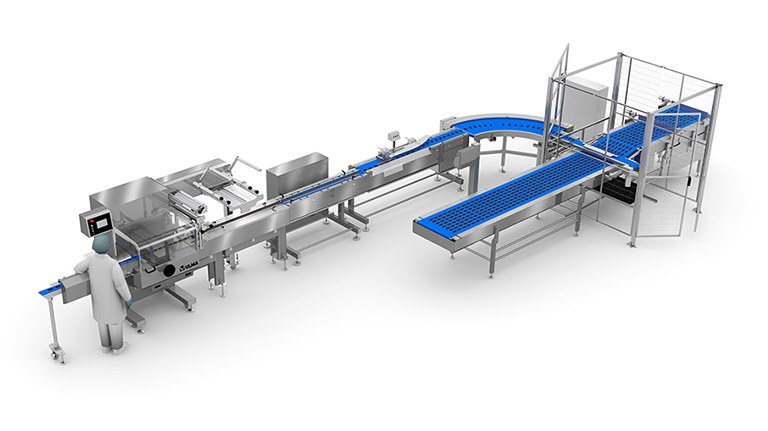

2. Securing the Product: The Case Sealer

How do you ensure your products are securely enclosed and ready for the next step? The case sealer provides the final, crucial seal.

The Case Sealer automatically closes and seals the top and/or bottom flaps of filled product cases, ensuring product integrity and tamper evidence. It offers consistent, strong seals using either tape or hot-melt glue, significantly boosting speed and reliability compared to manual methods.

2.2 Benefits: Consistency, Strength, and Speed

Automating case sealing delivers significant benefits in consistency, strength, and speed. Manual sealing is slow, inconsistent, and prone to errors, leading to poorly sealed cases that can open during transit, resulting in product damage or loss. An automated case sealer ensures every case is sealed with uniform pressure and adhesive application, creating a consistently strong and reliable closure. This consistency is vital for maintaining product integrity and presenting a professional image. Furthermore, automated sealers operate at much higher speeds than manual methods, keeping pace with high-volume production lines and eliminating bottlenecks. For instance, a pharmaceutical company relies on the consistent, strong seals provided by an automated case sealer to ensure product safety and regulatory compliance, knowing that each case is securely closed.

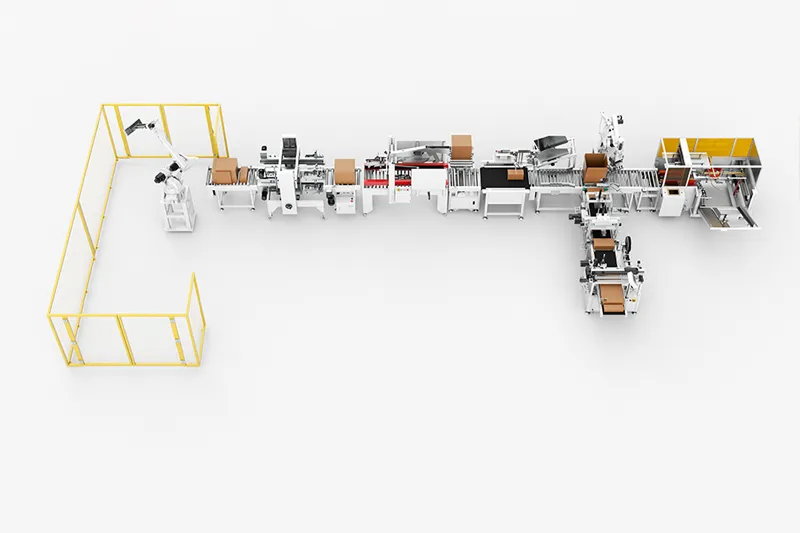

3. The Powerhouse: Robotic Palletizing

Ready to transform your labor-intensive palletizing into a flexible, precise, and gentle operation? Robotic palletizing is the answer.

Robotic palletizing offers unparalleled flexibility, precision, and gentle handling compared to older mechanical systems, efficiently stacking various box sizes into complex, stable pallet patterns. These robots eliminate manual labor, reduce injuries, and optimize pallet loads for safe transport and storage.

3.1 Contrasting with Old Mechanical Palletizers

For decades, mechanical palletizers were the standard, using fixed patterns and complex machinery to stack cases. While effective, they lacked flexibility, were difficult to reconfigure for different products, and often handled cases with less finesse. Robotic palletizers represent a significant leap forward. Unlike their mechanical predecessors, robots offer:

- Flexibility: Easily reprogrammable for different product sizes, weights, and stacking patterns with minimal downtime.

- Precision: Robots place cases with extreme accuracy, creating tighter, more stable pallet loads.

- Gentle Handling: Their controlled movements reduce the risk of product damage, especially for fragile items.

For example, a logistics hub handling diverse products, from small electronics to large household appliances, can use a single robotic palletizer to manage all their needs, simply by changing the program. Joyda Totalpack’s robotic palletizers are designed for adaptability and high performance, making them a cornerstone of modern end-of-line automation.

3.2 Handling Various Box Sizes and Complex Pallet Patterns

One of the standout advantages of robotic palletizers is their ability to handle a wide variety of box sizes and create complex, optimized pallet patterns. Traditional mechanical palletizers often require significant retooling or even replacement when product dimensions change. Robotic systems, however, can be quickly reprogrammed to accommodate new box sizes, weights, and even different product types on the same line.

Furthermore, robots excel at creating intricate and stable pallet patterns that maximize load stability and space utilization. They can interlock cases, create overhangs, or adjust for irregular shapes, ensuring the pallet load is robust enough for long-distance shipping and warehousing. For instance, a food manufacturer packaging various sizes of cereal boxes can use one robotic palletizer to create perfectly stacked, stable pallets for each product, optimizing truck loading and reducing transit damage. This versatility makes robotic palletizing an indispensable asset for dynamic production environments.

4. Ready for Shipment: The Automatic Stretch Wrapper

How do you ensure your perfectly stacked pallets remain stable and protected during transit? The stretch wrapper provides the final, critical layer of security.

Automatic stretch wrappers provide consistent load stability for palletized products, significantly improving safety during transport and storage while reducing film waste. They ensure every pallet is securely wrapped, protecting products from damage, dust, and moisture, and optimizing material usage.

4.1 Consistent Load Stability, Improved Safety, and Reduced Film Waste

The final step in end-of-line automation is securing the palletized load with a Stretch Wrapper. This machine automatically applies layers of stretch film around the entire pallet, binding all the individual cases together into a cohesive, stable unit. The benefits are multifaceted:

- Consistent Load Stability: Automated wrappers apply film with consistent tension and overlap, ensuring every pallet is wrapped identically. This prevents cases from shifting or falling during transport, a common cause of product damage and workplace accidents.

- Improved Safety: Stable loads are safer to handle, reducing the risk of injuries during forklift operations or manual handling.

- Reduced Film Waste: Modern stretch wrappers are designed to optimize film usage, applying only the necessary amount with precise tension. This minimizes material costs and environmental impact compared to inconsistent manual wrapping.

For example, a distribution center shipping fragile electronics relies on automatic stretch wrappers to ensure each pallet arrives intact, protecting valuable goods and preventing costly returns. Joyda Totalpack’s stretch wrappers are engineered for efficiency and reliability, providing the ultimate protection for your products.

5. Cumulative ROI of End-of-Line Automation

Still seeing end-of-line automation as just an expense? It’s a strategic investment with compounding returns.

Automating the entire end-of-line process—case erecting, sealing, and palletizing—delivers significant cumulative ROI by drastically reducing labor costs, minimizing product damage, improving throughput, enhancing workplace safety, and optimizing material usage, leading to a rapid and substantial return on investment.

5.1 The Power of an Integrated System

The true power of end-of-line automation lies in the cumulative benefits of integrating all these components into a seamless system. Each machine—the case erector, case sealer, robotic palletizer, and stretch wrapper—contributes to efficiency, but their combined effect is transformative.

- Labor Cost Reduction: Eliminating manual tasks for case assembly, sealing, and palletizing frees up significant labor, allowing personnel to be reallocated to higher-value activities.

- Increased Throughput: Automated machines operate at much higher and more consistent speeds than humans, dramatically increasing your overall production capacity.

- Reduced Product Damage & Waste: Consistent case formation, secure sealing, precise palletizing, and stable wrapping all contribute to fewer damaged products, less material waste, and fewer returns.

- Enhanced Workplace Safety: Automating physically demanding tasks reduces the risk of repetitive strain injuries and accidents.

- Improved Traceability & Quality: Integrated systems can provide data on every step, enhancing quality control and traceability.

For example, a large-scale food processing plant implementing a full end-of-line automation solution could see a reduction in labor costs by 50% in that area, a 30% increase in throughput, and a 15% decrease in product damage within the first year, leading to a rapid and substantial ROI.

Conclusion:

End-of-line automation, encompassing case erecting, sealing, and palletizing, is no longer a luxury but a strategic imperative for businesses aiming to maximize efficiency and profitability. By replacing strenuous, time-consuming manual tasks with integrated, high-performance machinery—from case erectors and sealers to robotic palletizers and stretch wrappers—you can achieve unparalleled consistency, speed, and product integrity. This comprehensive approach not only delivers significant cumulative ROI through reduced labor, waste, and damage but also enhances workplace safety and prepares your operations for future growth.