Integrating robotic palletizers and automatic stretch wrappers delivers significant ROI far beyond eliminating heavy lifting, justifying upfront costs through drastically reduced labor expenses, increased throughput, minimized product damage, and lower injury rates. This strategic investment also provides critical intangible benefits like enhanced flexibility, optimized space, improved safety, and consistent load integrity, positioning businesses for future growth and competitiveness.

Investing in advanced automation like robotic palletizers and automatic stretch wrappers often comes with a significant upfront cost, which can give financial decision-makers pause. However, viewing these technologies merely as expenses misses their profound impact on profitability and operational efficiency. This article directly addresses the initial investment by demonstrating the tangible return on investment (ROI) and the critical, albeit less quantifiable, strategic benefits. Discover how Joyda Totalpack’s integrated solutions can transform your end-of-line operations into a powerful engine for growth and competitiveness.

Table of Contents

- The Tangible ROI: Calculating Your Payback Period

- The Intangible (But Critical) Benefits

- A Seamless Partnership: How the Palletizer and Wrapper Work Together

- Robotic Palletizers and Stretch Wrappers: A Strategic Move

1. The Tangible ROI: Calculating Your Payback Period

How quickly can robotic palletizers and stretch wrappers pay for themselves? The numbers reveal a compelling story of cost savings and increased output.

The tangible ROI of integrating robotic palletizers and stretch wrappers is calculated through significant reductions in labor costs, dramatically increased throughput, minimized product damage, and lower injury rates, all contributing to a rapid payback period and substantial long-term savings.

1.1 Reduced Labor Costs: Replacing Multiple Shifts of Manual Labor

One of the most immediate and impactful tangible benefits is the drastic reduction in labor costs. Manual palletizing and stretch wrapping are physically demanding tasks that often require multiple workers per shift, sometimes across 2-3 shifts daily. A single robotic palletizer, often paired with an automatic stretch wrapper, can replace this entire workforce. For example, a facility operating three shifts might employ 6-9 workers solely for end-of-line tasks. Automating this can eliminate those positions, leading to annual savings of hundreds of thousands of dollars in wages, benefits, and associated overhead. This direct cost saving is often the largest component in calculating a rapid payback period for the initial investment. Joyda Totalpack’s solutions are designed to maximize labor efficiency, freeing up your workforce for more skilled roles.

| Cost Factor | Manual Palletizing & Wrapping | Automated System | Annual Savings Potential |

| Wages | High (multiple shifts) | Low (supervision) | Significant |

| Benefits | High | Low | Significant |

| Overhead | Training, HR, safety | Reduced | Moderate |

| Turnover | High | Low | Reduced recruitment costs |

1.2 Increased Throughput: Running 24/7 with Minimal Downtime

Robotic palletizers and automatic stretch wrappers can operate continuously, 24 hours a day, 7 days a week, with minimal downtime for breaks, shift changes, or fatigue. This capability dramatically increases throughput compared to human operators. While a human might slow down over a shift, a robot maintains consistent speed and precision. This means more products can be processed and shipped in the same timeframe, directly boosting production capacity and revenue. For instance, a food processing plant might increase its daily pallet output by 30-50% by automating, allowing them to meet higher demand without expanding their physical footprint. This consistent, high-speed operation translates directly into greater profitability and market responsiveness.

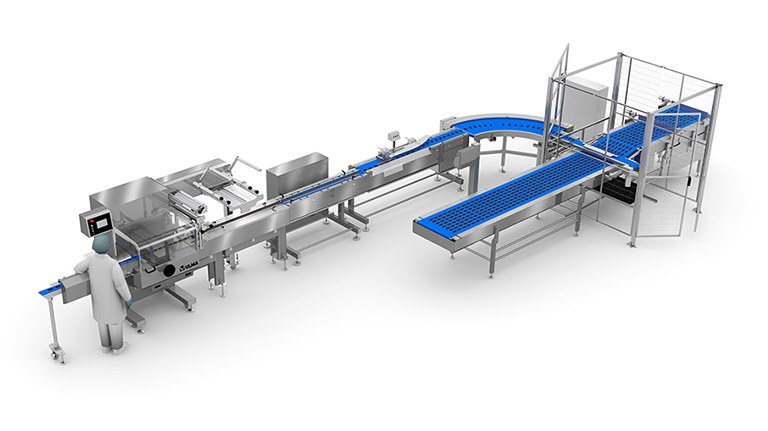

1.3 Reduced Product Damage: Gentle Robotic Handling vs. Manual Throwing

Manual palletizing, especially with heavy or awkwardly shaped products, often involves less-than-gentle handling, leading to dropped cases, crushed corners, and damaged goods. This results in costly product write-offs, returns, and customer dissatisfaction. Robotic palletizers, however, are programmed for precise and gentle handling. They pick up and place cases with consistent force and accuracy, minimizing impacts and ensuring products remain intact. For example, a company packaging fragile glass bottles or delicate electronics will see a significant reduction in breakage and damage claims by switching to robotic handling. This reduction in damaged goods directly impacts your bottom line by preserving product value and enhancing customer satisfaction.

1.4 Lower Injury Rates: Eliminating Costly Workplace Injuries from Heavy Lifting

Palletizing is one of the most physically demanding and injury-prone tasks in a warehouse or production facility. Repetitive heavy lifting leads to a high incidence of back injuries, strains, and other musculoskeletal disorders. These injuries result in significant costs: workers’ compensation claims, lost productivity, increased insurance premiums, and potential legal fees. Integrating robotic palletizers completely eliminates the need for human workers to perform heavy lifting. This drastically reduces injury rates, creating a safer work environment and cutting associated costs. For instance, a beverage distributor previously facing multiple back injury claims annually can virtually eliminate them with automation, saving substantial amounts in direct and indirect injury-related expenses.

2. The Intangible (But Critical) Benefits

Beyond the numbers, robotic palletizers and stretch wrappers offer strategic advantages that are harder to quantify but vital for long-term success.

The intangible benefits of integrating robotic palletizers and stretch wrappers include enhanced flexibility for new products, optimized space utilization through denser pallets, improved worker safety and morale, and consistent load integrity, all of which are critical for long-term competitiveness and operational excellence.

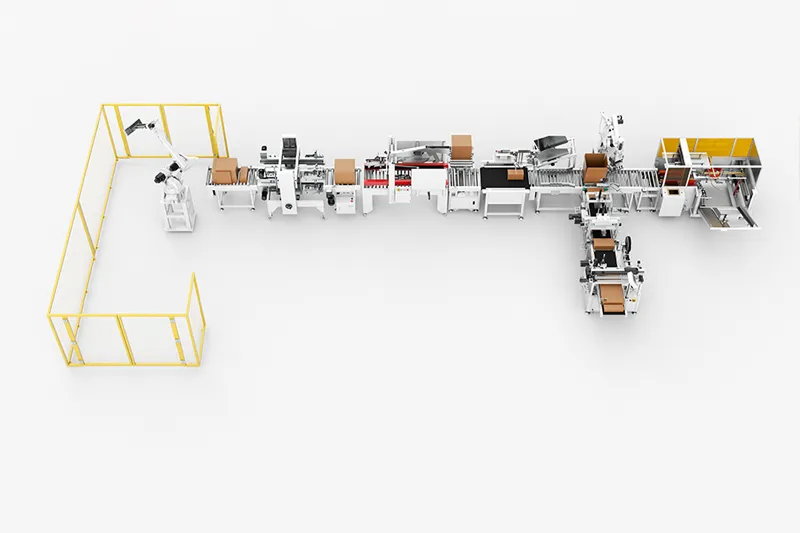

2.1 Flexibility: Easy Re-programming for New Products or Pallet Patterns

One of the most significant intangible benefits of robotic palletizers is their inherent flexibility. Unlike older, fixed-pattern mechanical palletizers that require extensive retooling for product changes, robots can be easily reprogrammed. This means adapting to new product sizes, weights, or desired pallet patterns is a matter of a few clicks, not days or weeks of engineering work. This agility is crucial in today’s rapidly changing market, allowing businesses to quickly introduce new products or respond to evolving customer demands without costly production line overhauls. For example, a co-packing facility handling diverse client products can quickly switch between different palletizing configurations, maximizing uptime and responsiveness.

2.2 Space Optimization: Creating Smaller, Denser Pallets

Robotic precision allows for more efficient pallet stacking. Robots can create tighter, more consistent pallet patterns, often leading to denser loads. This means you can fit more product onto each pallet, which translates to:

- Reduced Shipping Costs: More product per pallet means fewer pallets per shipment, lowering freight expenses.

- Optimized Warehouse Space: Denser pallets take up less floor space, increasing storage capacity without physical expansion.

For instance, by optimizing pallet patterns, a consumer goods company might reduce its required warehouse footprint by 10-15%, or significantly cut down on the number of trucks needed for distribution, leading to substantial, ongoing savings.

2.3 Improved Safety & Morale: Moving Human Workers to More Skilled, Less Strenuous Roles

While the reduction in injury rates is a tangible cost saving, the broader impact on workplace safety and employee morale is an invaluable intangible benefit. By removing workers from dangerous, repetitive, and physically exhausting tasks like palletizing, companies demonstrate a commitment to employee well-being. This can lead to:

- Higher Morale: Employees feel valued when moved to safer, more engaging roles.

- Reduced Turnover: A better work environment attracts and retains talent.

- Upskilling Opportunities: Workers can be trained for more skilled positions, such as robot operation, maintenance, or quality control, enhancing their career development.

For example, instead of manually stacking heavy boxes, workers can oversee the automated line, perform quality checks, or manage inventory, leading to a more engaged and productive workforce.

2.4 Consistent Load Integrity: The Stretch Wrapper Ensures Safe Transport, Reducing Shipping Claims

The automatic stretch wrapper plays a critical role in ensuring consistent load integrity. Manual wrapping is often inconsistent, leading to loose loads that shift, tip, or get damaged during transit. An automatic wrapper applies film with precise, programmable tension and overlap, creating a consistently secure and stable pallet every time. This consistent load integrity directly translates to:

- Reduced Shipping Claims: Fewer damaged products mean fewer claims from customers or carriers.

- Enhanced Customer Satisfaction: Products arrive in pristine condition, reinforcing brand quality.

- Improved Supply Chain Reliability: Predictable and safe transport.

For instance, a company shipping high-value electronics can significantly reduce transit damage and associated costs by ensuring every pallet is perfectly secured by an automatic stretch wrapper.

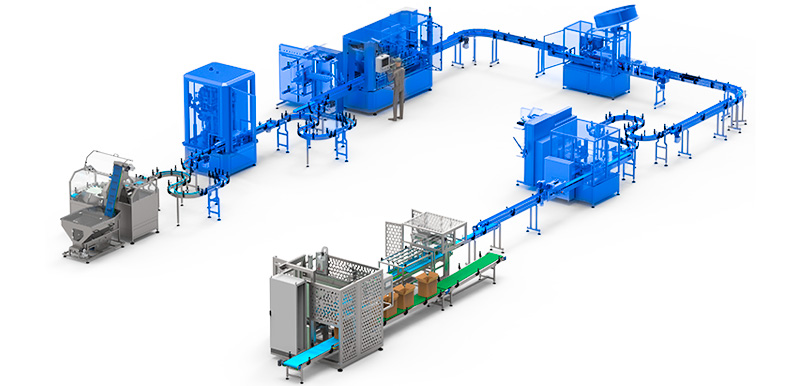

3. A Seamless Partnership: How the Palletizer and Wrapper Work Together

How do these two powerful machines create a cohesive, efficient end-of-line system? It’s all about seamless integration.

The robotic palletizer and automatic stretch wrapper form a seamless partnership, with finished pallets exiting the palletizer directly into the wrapper. This integrated flow eliminates manual intervention between stages, ensuring continuous operation, maximum efficiency, and a fully secured load ready for immediate shipment.

3.1 Integrated Flow from Palletizer to Wrapper

The true efficiency of end-of-line automation is realized when the robotic palletizer and automatic stretch wrapper work in perfect harmony as an integrated system. Once the robotic palletizer has completed stacking a full pallet of products, it automatically discharges the pallet directly onto a conveyor system that feeds it into the automatic stretch wrapper. This seamless, automated transfer eliminates any manual handling between these two critical stages.

There’s no need for a forklift operator to move the pallet, nor for a human to manually wrap it. The flow is continuous and uninterrupted. For example, a pallet of bottled water, once stacked by the robot, immediately moves into the wrapper, which then applies the protective film. This integrated approach ensures maximum throughput, minimizes potential bottlenecks, and guarantees that every pallet is not only perfectly stacked but also securely wrapped and ready for immediate storage or shipment. Joyda Totalpack specializes in designing and implementing these fully integrated end-of-line solutions.

4. Robotic Palletizers and Stretch Wrappers: A Strategic Move

Beyond immediate gains, what does this investment mean for your company’s future? It’s about securing a competitive edge.

Investing in robotic palletizers and automatic stretch wrappers is a strategic move for future growth and competitiveness, enabling businesses to scale operations, adapt to market changes, attract and retain talent, and maintain a leading edge through superior efficiency, quality, and safety.

4.1 Positioning for Future Growth and Competitiveness

Integrating robotic palletizers and automatic stretch wrappers is more than just an operational upgrade; it’s a strategic move that positions your company for future growth and enhanced competitiveness.

- Scalability: Automated systems can easily scale to meet increased production demands without significant additional labor costs, allowing your business to grow without being constrained by end-of-line capacity.

- Adaptability: The flexibility of robotic systems means you can quickly adapt to new product lines, packaging changes, and evolving market trends, keeping you agile and responsive.

- Talent Attraction & Retention: Modern, automated facilities are more attractive to skilled workers, helping you recruit and retain top talent by offering safer, more engaging roles.

- Competitive Edge: Superior efficiency, consistent quality, and reduced costs give you a significant advantage over competitors relying on manual processes. You can offer better pricing, faster delivery, and more reliable products.

For instance, a rapidly expanding e-commerce fulfillment center can leverage automation to handle fluctuating order volumes and diverse product mixes, ensuring they remain competitive in a fast-paced market. This investment is about building a resilient, efficient, and future-ready operation.

Conclusion:

The decision to integrate robotic palletizers and automatic stretch wrappers is a strategic one that extends far beyond simply automating heavy lifting. While the tangible ROI—through reduced labor costs, increased throughput, minimized product damage, and lower injury rates—is compelling, the intangible benefits are equally critical. Enhanced flexibility, optimized space, improved safety and morale, and consistent load integrity all contribute to a more robust, efficient, and competitive operation. This investment is not merely an expense; it’s a foundational step towards future growth, operational excellence, and a stronger market position.