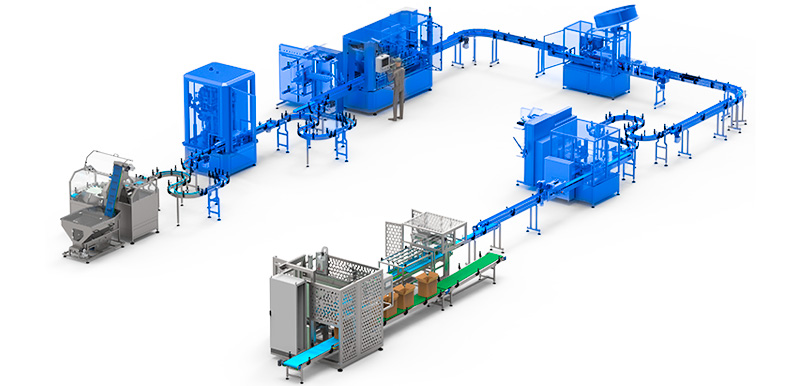

A complete and efficient packaging system operates like a well-conducted orchestra, where each component—from case erectors and checkweighers to cartoning machines, labelers, case sealers, robotic palletizers, and stretch wrappers—plays a vital, integrated role. This seamless automation, orchestrated by central control systems, streamlines output, ensures quality, and maximizes efficiency from start to finish.

Imagine a symphony orchestra where every instrument plays its part in perfect harmony, creating a beautiful, cohesive sound. A modern, efficient packaging line operates in much the same way. Each machine, from the moment a product enters the line until it’s ready for shipment, plays a vital role, contributing to a seamless flow of production. Without proper coordination, the entire process can fall out of tune, leading to bottlenecks, errors, and wasted resources. This guide will introduce you to the essential components of a complete packaging system, highlighting how Joyda Totalpack integrates these elements to create a perfectly orchestrated, high-performance solution for your business.

Table of Contents

- The Beginning & Middle of the Line

- The Power of End-of-Line Automation

- The Secret Sauce: Integration and Control

- Seamless Integration: The Key to True Efficiency

The Infographic Flow:

Case Erector → Checkweigher → Cartoning/Filling Machine → Labeling Machine → Case Sealer → Palletizing Robot → Stretch Wrapper

1. The Beginning & Middle of the Line

Where does a product’s packaging journey truly begin, and how does it get ready for its final enclosure? It starts with precision and verification.

The beginning and middle of a packaging line involve core processes: the Case Erector forms boxes, the Checkweigher ensures product weight accuracy, the Cartoning/Filling Machine inserts products, the Labeling Machine applies identification, and the Case Sealer securely closes the packages, all contributing to product integrity and readiness.

1.1 Core Packaging Process: Case Erector, Checkweigher, Labeling Machine, and Case Sealer

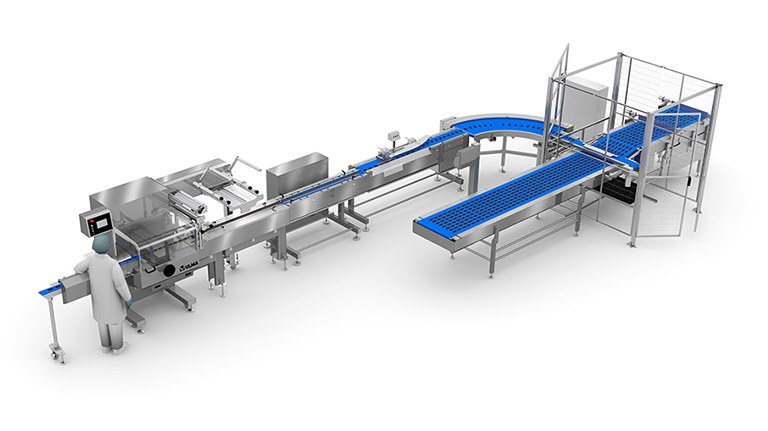

The initial and intermediate stages of a packaging line are crucial for preparing products and their primary packaging.

- Case Erector: This machine kicks off the process by taking flat cardboard blanks and automatically folding them into three-dimensional boxes, sealing the bottom flaps. It provides a consistent, ready-to-fill container. For example, it ensures every carton for mobile phones is perfectly formed before products are inserted.

- Checkweigher: Positioned after filling, the checkweigher precisely measures the weight of each product. It ensures compliance with regulations, prevents product giveaway (overfilling), and detects underfilled packages, automatically rejecting any non-compliant items. This is vital for quality control, such as ensuring every bag of coffee meets its declared weight.

- Cartoning/Filling Machine: This is where the product itself enters the package. Depending on the product, this could be a volumetric filler for liquids, a multi-head weigher for snacks, or a robotic pick-and-place system for delicate items. Its role is to accurately and efficiently place the product into its primary packaging.

- Labeling Machine: Once filled, products often need identification. The labeling machine applies labels with product information, barcodes, branding, and regulatory details. Precision is key to ensure labels are straight, secure, and legible, like applying a nutritional label to a food product.

- Case Sealer: After products are packed and labeled, the case sealer closes and seals the top and/or bottom flaps of the outer cases, typically using tape or hot-melt glue. This secures the product for transport and provides tamper evidence. For instance, it seals the cartons containing multiple units of perfume bottles.

These machines form the backbone of the packaging process, ensuring products are correctly contained, verified, and identified before the final stages.

| Machine Type | Primary Role | Example Application |

| Case Erector | Forms and seals bottom of empty boxes. | Preparing cartons for bottled beverages. |

| Checkweigher | Verifies product weight, rejects non-compliant. | Ensuring accurate weight of snack bags. |

| Cartoning/Filling | Inserts product into primary packaging. | Filling detergent into bottles. |

| Labeling Machine | Applies product information and branding. | Adding ingredient labels to food jars. |

| Case Sealer | Closes and seals filled cases. | Sealing boxes of books for shipment. |

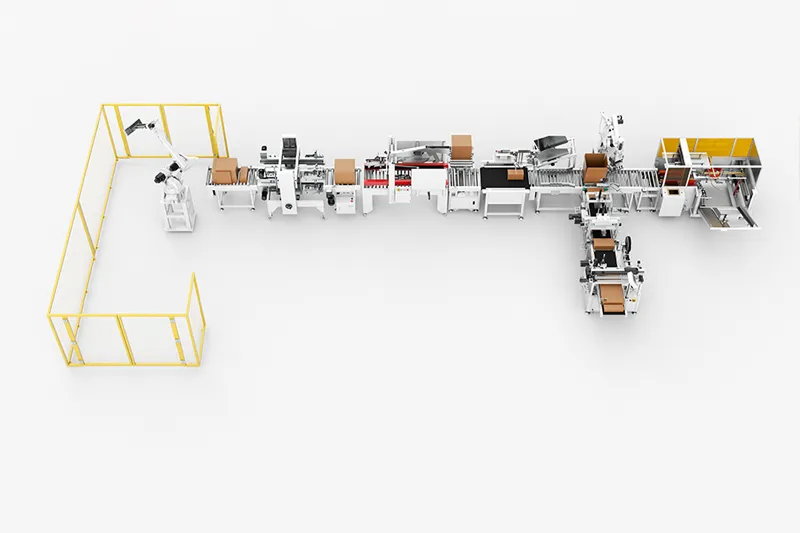

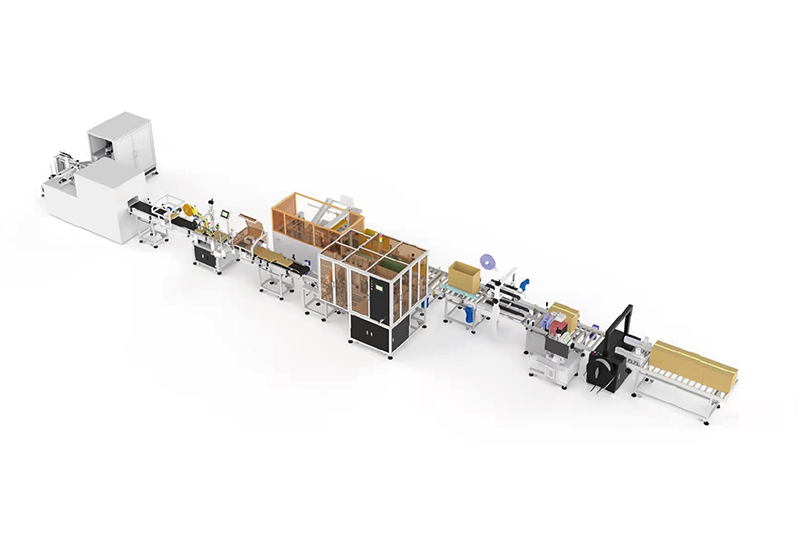

2. The Power of End-of-Line Automation

How do products transition from individual packages to ready-to-ship units? End-of-line automation is the key.

End-of-line automation, primarily driven by the Palletizing Robot and Stretch Wrapper, is the culmination of the packaging process, transforming individual cases into stable, secure, and transport-ready pallet loads. This prepares goods efficiently for warehousing, distribution, and global shipment.

2.1 The Culmination: Palletizing Robot and Stretch Wrapper

The final stages of a complete packaging system, known as end-of-line automation, are where individual products are consolidated and prepared for the rigors of warehousing and distribution. This is where the “orchestra” reaches its crescendo, preparing goods for their journey to the customer.

- Palletizing Robot: After cases are sealed, the palletizing robot takes over the heavy lifting. It automatically picks up individual cases and precisely stacks them onto pallets in pre-programmed patterns. This creates stable, uniform loads, maximizing space and preventing damage during transit. For example, a robot can efficiently stack cases of household appliances onto pallets, far exceeding manual capabilities in speed and consistency. Joyda Totalpack’s robotic palletizers offer flexibility for various product sizes and stacking patterns.

- Automatic Stretch Wrapper: Once a pallet is fully stacked, it moves to the automatic stretch wrapper. This machine applies layers of stretch film around the entire pallet load, securing all the cases together. This stabilization prevents shifting during transport, protects against dust and moisture, and provides tamper evidence. For instance, a pallet of medical supplies is securely wrapped to ensure its integrity from the factory to the hospital.

These end-of-line components are critical for ensuring that products arrive at their destination in perfect condition, ready for the world.

3. The Secret Sauce: Integration and Control

What truly makes a packaging line efficient, beyond just having great machines? It’s how they all work together.

The real magic of an efficient packaging system lies in the seamless integration and communication of all machines via a central control system, such as a PLC or SCADA. This “secret sauce” orchestrates the entire line, ensuring synchronized operation, real-time monitoring, and optimized performance.

3.1 Synchronized Operation via Central Control Systems

Having individual, high-performance machines is a good start, but the “secret sauce” that transforms them into a truly efficient packaging system is seamless integration and central control. This means all machines—from the case erector to the stretch wrapper—are connected and communicate with each other through a central control system, typically a Programmable Logic Controller (PLC) or a Supervisory Control and Data Acquisition (SCADA) system.

This central brain orchestrates the entire line, ensuring synchronized operation. For example, if the packing machine temporarily slows down, the case erector might automatically reduce its output to prevent a backlog, and the palletizing robot might adjust its speed accordingly. This real-time communication and coordination prevent bottlenecks, optimize throughput, and minimize downtime.

Furthermore, these control systems allow for:

- Real-time Monitoring: Operators can see the status of every machine, identify issues instantly, and track production metrics.

- Recipe Management: Quick changeovers for different products by loading pre-set parameters for all machines from a central interface.

- Predictive Maintenance: Data from machines can signal potential issues before they cause breakdowns, allowing for proactive maintenance.

Joyda Totalpack excels in providing comprehensive system integration, ensuring that all components work together flawlessly, often with custom-developed software that integrates seamlessly with client ERP systems. This level of integration is what truly unlocks maximum efficiency and reliability.

| Integration Aspect | Benefit for Efficiency |

| Centralized Control | Single point of command for the entire line. |

| Machine Communication | Prevents bottlenecks, optimizes flow. |

| Real-time Data | Enables quick problem-solving and process improvement. |

| Recipe Management | Fast and accurate product changeovers. |

4. Seamless Integration: The Key to True Efficiency

What’s the ultimate takeaway for building a high-performing packaging line? It’s about the whole being greater than the sum of its parts.

While each component in a packaging line is vital, their seamless integration and synchronized operation, orchestrated by intelligent control systems, are what truly create maximum efficiency. This holistic approach ensures a smooth, high-throughput, and reliable packaging process from start to finish.

4.1 The Whole is Greater Than the Sum of Its Parts

In the world of packaging automation, it’s easy to focus on the impressive capabilities of individual machines. However, the ultimate truth is that a packaging line’s true efficiency and performance are not determined by the strength of its individual components, but by how seamlessly they are integrated and how effectively they work together. A powerful palletizing robot is only as efficient as the case sealer feeding it, and a high-speed filler is limited by the speed of the case erector.

Joyda Totalpack understands that the “orchestra” must be perfectly conducted. Our expertise lies not just in manufacturing robust individual machines but in designing and integrating complete, turnkey packaging solutions. We ensure that every component communicates, every transition is smooth, and every process is optimized. This holistic approach eliminates bottlenecks, reduces manual intervention, minimizes errors, and maximizes throughput, ultimately delivering a packaging system that is reliable, scalable, and truly efficient. It’s this seamless integration that transforms a collection of machines into a powerful, unified production engine.

Conclusion:

Building a complete and efficient packaging system is like conducting a finely tuned orchestra, where each component plays a vital role in perfect harmony. From the initial case erection and precise checkweighing, through accurate cartoning, labeling, and secure case sealing, to the powerful end-of-line automation of robotic palletizing and stretch wrapping—every step is critical. However, the true magic lies in the seamless integration and central control that orchestrates these machines into a cohesive, high-performance system. This holistic approach ensures streamlined output, consistent quality, and maximum efficiency from start to finish.