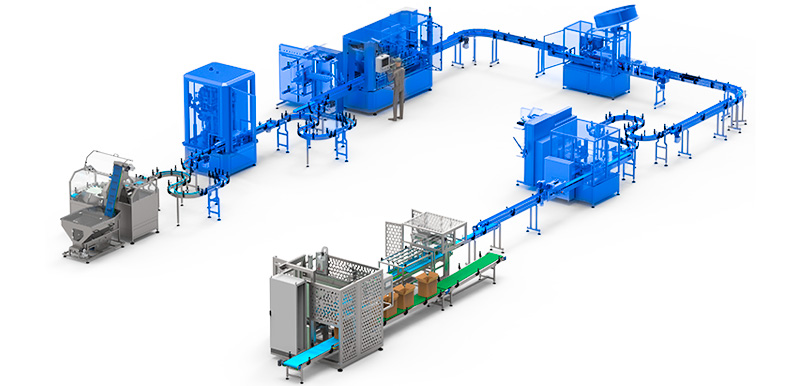

Building a fully automated packaging line from unboxing to palletizing integrates specialized machines like case erectors, checkweighers, auto cartoning machine, labelers, case sealers, palletizing robots, and stretch wrappers into one smart system. This comprehensive solution eliminates manual bottlenecks, cuts labor costs, ensures consistent quality, and maximizes efficiency and ROI.

Manual or semi-automated packaging creates bottlenecks, raises labor costs, and leads to inconsistent quality. These issues hurt profits and growth. Imagine a packaging line where every step, from initial boxing to final palletizing, is precise, fast, and smart. This article outlines the key components and seamless integration needed for a fully automated packaging line, showing how a complete solution provider like Joyda Totalpack can transform your operations.

Table of Contents

- The Starting Point: Case Erecting & Unpacking

- Ensuring Accuracy: The Checkweigher

- The Assembly Stage: Auto-filling, Labeling & Sealing

- The Grand Finale: Palletizing & Stabilization

- Overall Benefits of a Fully Automated Packaging Line

1. The Starting Point: Case Erecting & Unpacking

Wondering where an automated packaging line begins? It starts with creating the perfect box.

The first step for a fully automated packaging line is the Case Erector, which automatically forms flat cardboard blanks into ready-to-fill boxes. This creates a uniform base for all subsequent processes, significantly boosting line speed and reducing repetitive strain injuries from manual assembly.

1.1 The Role of the Case Erector/Opener

The Case Erector is the foundational machine. It takes flat cardboard blanks and automatically folds them into 3D boxes, sealing the bottom flaps, often with hot-melt adhesive. For example, in a mobile phone line, it ensures every carton is perfectly square and consistent. Without this precision, later automated steps would fail. Joyda Totalpack ‘s case erectors provide high-speed, consistent performance, forming the base of an efficient line.

| Feature | Benefit for Automation |

| Automatic Folding | Eliminates manual assembly, boosts speed. |

| Bottom Sealing | Ensures structural integrity for filling. |

| Uniform Output | Critical for seamless machine interaction. |

| High Speed | Matches high-speed production lines. |

1.2 Benefits: Speed and Injury Reduction

Case erectors offer immediate benefits in speed and reducing repetitive strain injuries (RSIs). Manual case Erecting is slow and labor-intensive, creating bottlenecks. An automated erector processes dozens or hundreds of cases per minute, setting the pace for the entire line.

Repetitive motions in manual Erecting cause RSIs, leading to worker discomfort and absenteeism. Automating this task protects workers, improves ergonomics, and allows labor to be reallocated to more complex roles. For example, in a book packaging line, automation speeds up the process and frees workers from a monotonous, harmful task.

2. Ensuring Accuracy: The Checkweigher

Concerned about product consistency and compliance? The checkweigher is your essential guardian for precise weight.

A checkweigher is the critical “quality control checkpoint” in an automated line, precisely measuring each product’s weight. It ensures compliance, automatically rejects under- or overweight items, preventing costly errors, product giveaways, and potential fines.

2.1 The Checkweigher’s Role as Quality Control

The Checkweigher is vital for quality control, positioned after filling. It measures every item’s weight in real-time. This ensures compliance with net weight regulations, preventing legal issues and customer dissatisfaction. It also stops “product giveaway” (overweight packages) which wastes product, and “underweight” packages which damage brand reputation. For example, in a biscuit line, it ensures each pack has the exact weight, maintaining trust.

| Checkweigher Function | Direct Benefit |

| High-Speed Weighing | Maintains line speed. |

| Weight Compliance | Ensures regulatory adherence. |

| Underweight Detection | Prevents customer complaints. |

| Overweight Detection | Eliminates product giveaway. |

2.2 Ensuring Weight Compliance and Automatic Rejection

The checkweigher not only measures but also acts. It compares a product’s weight against pre-set tolerances. If outside the range, it automatically triggers a rejection mechanism (e.g., a pneumatic pusher) to remove the non-compliant package.

This automatic rejection is crucial for quality and efficiency. It eliminates slow, error-prone manual inspection. For instance, an underweight perfume bottle is immediately removed, preventing it from reaching the consumer. This ensures only perfectly weighted products proceed, guaranteeing consistent quality and protecting your brand.

3. The Assembly Stage: Auto-filling, Labeling & Sealing

Ready to see your products packaged? This stage involves precise filling, clear identification, and secure closure.

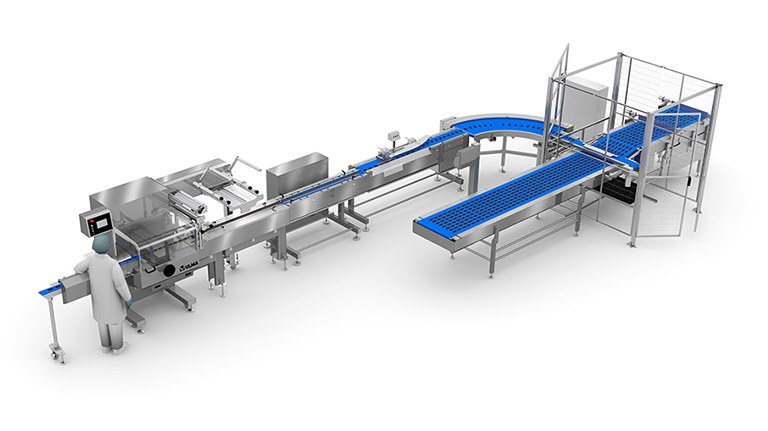

The assembly stage uses Auto-filling/Packing Machines for precise product insertion, Labeling Machines for accurate identification and branding, and Case Sealers (hot-melt or tape) for securely closing final packages, ensuring product integrity and presentation.

3.1 Auto-filling/Packing and Labeling Machines

After cases are erected and products checked, the next steps are precise product insertion and clear identification. The Auto-filling/Packing Machine efficiently places products into containers. This can be robotic pick-and-place for delicate items like mobile phones, or volumetric fillers for liquids. The goal is consistent, damage-free insertion at high speeds.

Next, the Labeling Machine applies labels with product info, barcodes, and branding. Precision ensures labels are straight, secure, and legible. For example, in a book line, the auto-filler places books, and the labeler applies product info. Joyda Totalpack’s machines ensure smooth product flow without bottlenecks.

| Machine Type | Key Benefit |

| Auto-filler | Speed, accuracy, damage prevention. |

| Labeler | Compliance, brand recognition, traceability. |

| Case Sealer | Product integrity, tamper evidence. |

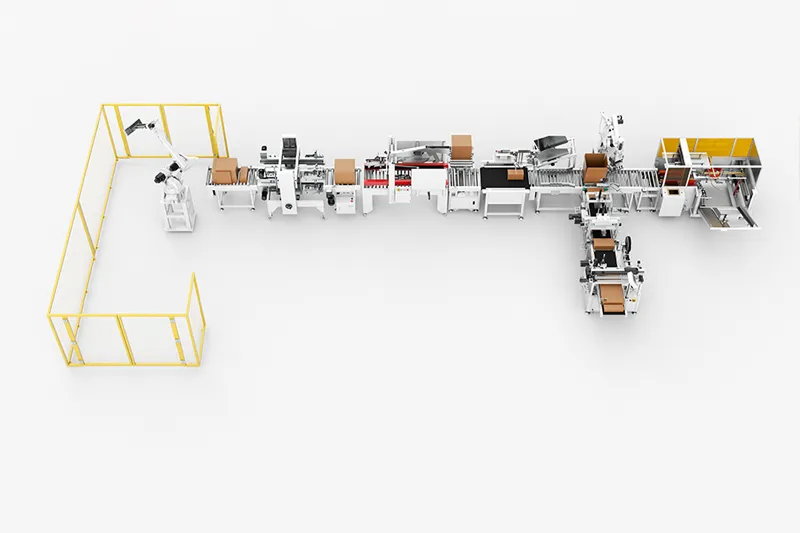

3.2 Introducing the Case Sealer for Secure Packaging

After filling and labeling, the Case Sealer closes and seals the top flaps of cartons, protecting the product and providing tamper evidence. It typically uses hot-melt adhesive or tape.

For example, after chocolates are cartoned, the case sealer applies hot-melt glue to the outer flaps for a secure, professional finish. Joyda Totalpack offers both hot-melt and tape sealers for reliability. A well-sealed package protects the product during transit and storage, presenting a professional image and ensuring it arrives in perfect condition.

4. The Grand Finale: Palletizing & Stabilization

Ready to turn individual packages into stable, transport-ready units? The final stages involve precise stacking and robust securing.

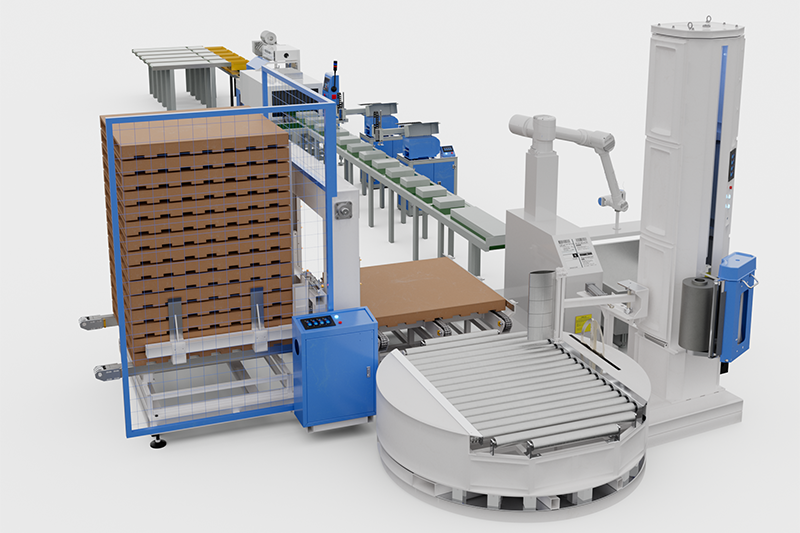

The final stage uses a Palletizing Robot to efficiently stack cases onto pallets in uniform patterns, followed by a Stretch Wrapper, which secures the load with stretch film. This ensures stable, safe, and transport-ready pallets, optimizing logistics and preventing damage during storage and transit.

4.1 The Palletizing Robot for Stable, Uniform Pallets

The Palletizing Robot marks the “grand finale,” transforming sealed cases into stable pallet loads. It picks up cases and precisely stacks them onto a pallet in a pre-programmed pattern. This creates a tightly interlocked, stable load for transport. For example, after sweeping robots are sealed, the robot stacks cartons to maximize stability and space.

Joyda Totalpack’s robots are versatile, handling various sizes and weights, and can be programmed for multiple stacking patterns. This automation eliminates labor-intensive manual palletizing, reducing errors and injuries. Consistent, stable pallets reduce product damage, saving costs and improving supply chain efficiency.

| Palletizing Robot Function | Key Advantage |

| Automatic Case Stacking | Eliminates manual labor, boosts speed. |

| Pattern Programming | Prevents load shifting, maximizes stability. |

| Versatility | Adaptable to diverse product lines. |

| High Throughput | Keeps pace with high-speed lines. |

4.2 The Stretch Wrapper for Secure Load Stabilization

After the palletizing robot stacks cases, the Stretch Wrapper prepares the load for transport. It automatically applies layers of stretch film around the entire pallet. This stabilizes the load, preventing shifting; protects against dust, moisture, and impacts; and provides tamper evidence.

For example, after a pallet of books is stacked, the stretch wrapper rotates the pallet, applying film tightly to create a robust unit. Joyda Totalpack’s stretch wrappers are efficient and apply film consistently, ensuring optimal load containment with minimal material. This final step is essential for safeguarding product integrity from factory to warehouse, minimizing shipping damage, and ensuring products arrive in pristine condition.

5. Overall Benefits of a Fully Automated Packaging Line

Looking for a comprehensive overview of the advantages of a fully automated packaging line? The benefits span efficiency, traceability, and significant ROI.

A fully automated packaging line offers unparalleled benefits: dramatically increased operational efficiency, enhanced product traceability, superior quality control, significant reductions in labor costs and material waste, and a strong return on investment. It transforms packaging into a streamlined, intelligent, and highly reliable process.

5.1 Unparalleled Efficiency and Traceability

The main benefits of an automated packaging line are efficiency and traceability. Integrating machines like case erectors, checkweighers, auto-fillers, labelers, case sealers, palletizing robots, and stretch wrappers creates a seamless, high-speed operation. Bottlenecks are gone, errors reduced, and throughput maximized. For example, a Joyda Totalpack line for sweeping robots can process hundreds of units per hour with consistent quality, far exceeding manual capabilities.

Automation also builds robust traceability. Sensors and software track every product’s journey. You know when a mobile phone batch was packaged, what materials were used, and machine performance. This is invaluable for quality control, recalls, and compliance, providing an auditable record for every product.

5.2 Significant ROI and Future-Proofing

Investing in an automated packaging line yields significant ROI. Reduced labor costs are a major factor, as machines handle repetitive tasks. Minimized material waste (due to precision) and optimized energy consumption cut operational expenses. Increased throughput and reduced downtime (thanks to predictive maintenance) boost production and revenue. For instance, a book packaging line achieves higher output with fewer errors, directly impacting profitability.

Beyond financial gains, an automated line future-proofs your operations. It offers flexibility to adapt to market changes, new products, and packaging trends. It also sets the stage for further integration with ERP systems and Industry 4.0 technologies, keeping your business competitive and agile.

Conclusion:

Building a fully automated packaging line is a strategic investment that transforms your operations into a cohesive, intelligent, and highly efficient system. From case Erecting and checkweighing, through auto-filling, labeling, and sealing, to robotic palletizing and stretch wrapping, every component works in harmony. This leads to increased efficiency, impeccable quality control, enhanced traceability, and a substantial return on investment. It eliminates bottlenecks, cuts costs, minimizes waste, and positions your business for growth.