Industry 4.0 packaging lines deliver a significantly higher ROI than traditional systems by drastically reducing operational costs, minimizing downtime through predictive maintenance, improving product quality, and offering unparalleled flexibility and scalability, leading to substantial long-term financial gains and competitive advantages.

In an era where efficiency and agility dictate market leadership, businesses are constantly evaluating their operational investments. The packaging sector, a critical link in the global supply chain, is no exception. While traditional packaging systems have served their purpose for decades, the emergence of Industry 4.0 technologies presents a compelling alternative. But beyond the hype, what’s the tangible return on investment (ROI) when comparing an Industry 4.0 packaging line to its conventional counterpart? This article delves into the financial and operational advantages, providing a clear picture of the real ROI offered by smart, integrated packaging solutions from companies like JOYDA TECH.

Table of Contents

- What Defines Industry 4.0 vs. Traditional Packaging Systems?

- How Do Operational Costs Differ: Industry 4.0 vs. Traditional?

- What is the Impact on Downtime and Maintenance ROI?

- How Does Quality and Waste Reduction Affect ROI?

- What is the Long-Term Strategic ROI of Industry 4.0 Packaging?

1. What Defines Industry 4.0 vs. Traditional Packaging Systems?

Are you wondering about the fundamental differences between the packaging lines of yesterday and the smart factories of tomorrow? Understanding these distinctions is crucial to grasping the true value proposition of Industry 4.0.

Industry 4.0 packaging systems are characterized by their interconnectedness, intelligence, and autonomy, leveraging IoT, AI, and real-time data analytics. In contrast, traditional systems are typically standalone, manually operated, and reactive, lacking the integrated communication and predictive capabilities that define modern automation.

1.1 Core Characteristics: Traditional Packaging Systems

Traditional packaging systems are typically characterized by their standalone nature and reliance on manual operation or basic automation. These systems often consist of individual machines—like a hot-melt sealing machine, a shrink-wrapping machine, or a cartoning machine—that operate independently with limited or no communication between them. Data collection, if it occurs, is often manual or through isolated systems, leading to data silos. For example, an operator might manually record throughput numbers from a labeling machine, which then needs to be entered into a separate spreadsheet. Maintenance is usually reactive (fixing breakdowns) or time-based (scheduled regardless of actual need). This multi-angle analysis reveals that while traditional systems are functional, they lack the agility, real-time visibility, and predictive capabilities that are becoming essential in today’s dynamic market. Their design often prioritizes mechanical robustness over digital intelligence.

| Characteristic | Description | Practical Limitation |

| Standalone Machines | Limited or no communication between units. | Bottlenecks due to lack of synchronization. |

| Manual Operation | High reliance on human intervention. | Prone to human error and slower changeovers. |

| Reactive Maintenance | Repairs only after a breakdown occurs. | Unplanned downtime and costly emergency repairs. |

| Isolated Data | Data collected in silos, not integrated. | Poor visibility into overall line performance. |

1.2 Core Characteristics: Industry 4.0 Packaging Systems

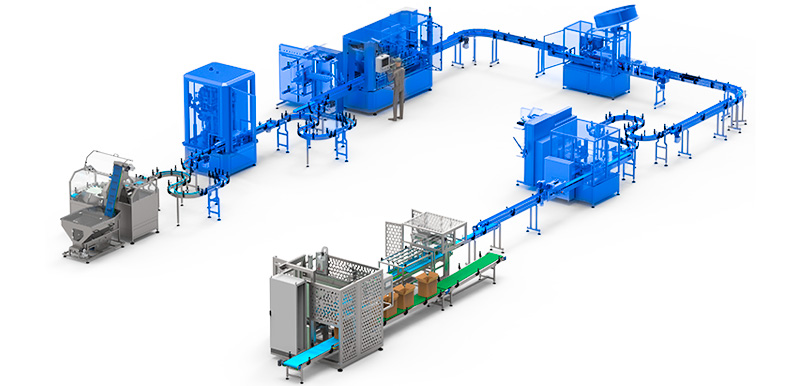

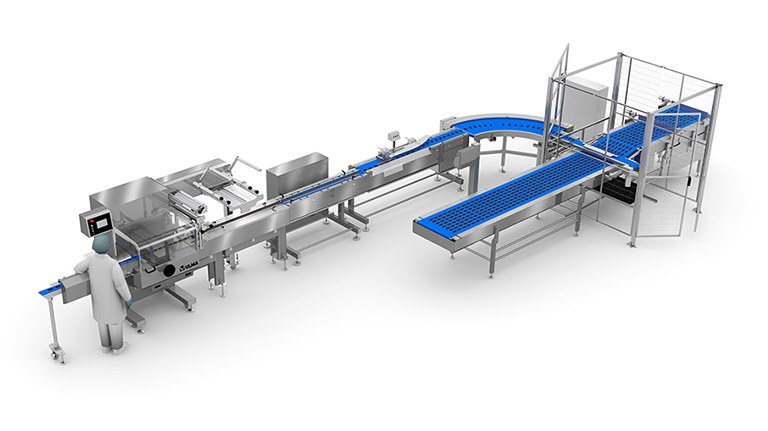

In stark contrast, Industry 4.0 packaging systems, like those designed and delivered by JOYDA TECH, are defined by their advanced digital integration and intelligence. These systems leverage the Internet of Things (IoT) to connect every machine, sensor, and control unit, enabling real-time data exchange. Artificial Intelligence (AI) and machine learning algorithms analyze this data to provide predictive insights, optimize performance, and even facilitate autonomous decision-making. For instance, a JOYDA TECH packaging line for mobile phones or books would feature smart cartoning machines, robotic palletizers, and hot-melt sealing machines that communicate seamlessly with each other and with a central ERP system via proprietary software. Maintenance is predictive, based on real-time condition monitoring. This approach offers unparalleled transparency, flexibility, and efficiency. The entire line acts as a cohesive, intelligent unit, capable of self-optimization and rapid adaptation to changing production demands, a stark difference from the rigid nature of traditional setups.

2. How Do Operational Costs Differ: Industry 4.0 vs. Traditional?

Are you looking to understand where the real cost savings lie when comparing modern and conventional packaging operations? The operational cost differences between Industry 4.0 and traditional systems are substantial and multifaceted.

Industry 4.0 packaging lines significantly reduce operational costs compared to traditional systems by optimizing energy consumption, minimizing labor requirements through automation, reducing material waste via precision control, and streamlining resource allocation, leading to a lower total cost of ownership.

2.1 Energy Consumption and Labor Efficiency

One of the most significant areas of cost differentiation lies in energy consumption and labor efficiency. Traditional packaging lines often operate with less optimized energy usage, as individual machines may not be integrated to collectively manage power. In contrast, Industry 4.0 systems, like those from JOYDA TECH, incorporate smart sensors and AI-driven energy management. For example, a smart shrink-wrapping machine can adjust its heating elements based on real-time film properties and ambient temperature, consuming only the necessary energy. Similarly, a hot-melt sealing machine can optimize its adhesive application temperature, reducing power draw.

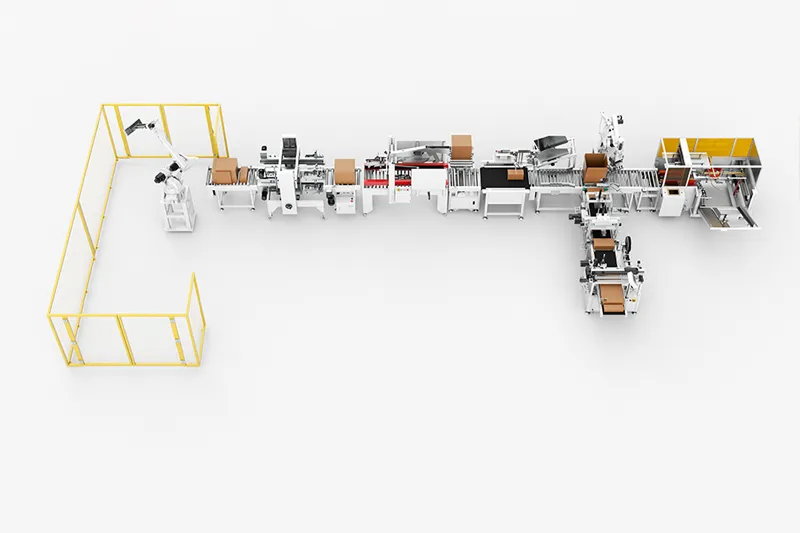

In terms of labor, traditional lines typically require more manual intervention for operation, monitoring, and changeovers. An Industry 4.0 line, however, leverages automation and robotics to perform repetitive tasks, such as precise product placement for perfumes or mobile phones, or automated palletizing for books. JOYDA TECH’s integrated solutions, with their proprietary software, can automate entire sequences, reducing the need for constant human oversight. This allows for a reallocation of labor to higher-value tasks like quality assurance, system monitoring, or strategic planning, leading to substantial savings in labor costs over time.

| Cost Factor | Traditional System | Industry 4.0 System (JOYDA TECH) |

| Energy Use | Less optimized, higher consumption. | AI-driven optimization, lower consumption. |

| Labor Needs | High for operation, monitoring, changeovers. | Reduced through automation, higher-value tasks. |

| Material Waste | Higher due to less precision. | Minimized through precise control and defect detection. |

| Maintenance | Reactive, costly emergency repairs. | Predictive, planned, lower overall cost. |

2.2 Material Waste and Resource Optimization

Material waste is another critical area where Industry 4.0 systems demonstrate superior ROI. Traditional packaging lines, lacking precise control and real-time feedback, often result in higher material consumption due to over-application, misalignments, or undetected defects. For instance, a conventional labeling machine might misapply labels on perfume bottles, leading to wasted labels and product rework. A hot-melt sealing machine might use excess adhesive, increasing material costs.

JOYDA TECH’s Industry 4.0 solutions, however, utilize advanced sensors and vision systems to ensure precise material application and immediate defect detection. A smart labeling machine can detect and correct misalignments in real-time, while an optimized hot-melt sealing machine applies the exact amount of adhesive needed. This precision minimizes waste of packaging materials like film, glue, and cardboard. Furthermore, integrated systems optimize resource allocation across the entire line. For example, the ERP integration ensures that packaging materials are ordered and consumed just-in-time, reducing storage costs and preventing obsolescence. This holistic approach to resource optimization directly translates into significant cost savings and a more sustainable operation.

3. What is the Impact on Downtime and Maintenance ROI?

Are you tired of unexpected breakdowns halting your production and eroding your profits? The impact of Industry 4.0 on downtime and maintenance ROI is a game-changer, moving from costly reactive fixes to efficient, predictive interventions.

Industry 4.0 packaging lines drastically reduce unplanned downtime and maintenance costs through predictive maintenance, real-time diagnostics, and remote monitoring. This proactive approach ensures higher machine availability, extends equipment lifespan, and delivers a superior ROI compared to the reactive, expensive maintenance cycles of traditional systems.

3.1 Predictive Maintenance vs. Reactive Breakdowns

The most profound impact of Industry 4.0 on downtime and maintenance ROI comes from the shift from reactive to predictive maintenance. In traditional systems, maintenance is often performed only after a machine breaks down, leading to costly unplanned downtime, emergency repairs, and lost production. For example, a sudden failure of a hot-melt sealing machine on a biscuit packaging line can halt the entire operation, resulting in significant financial losses.

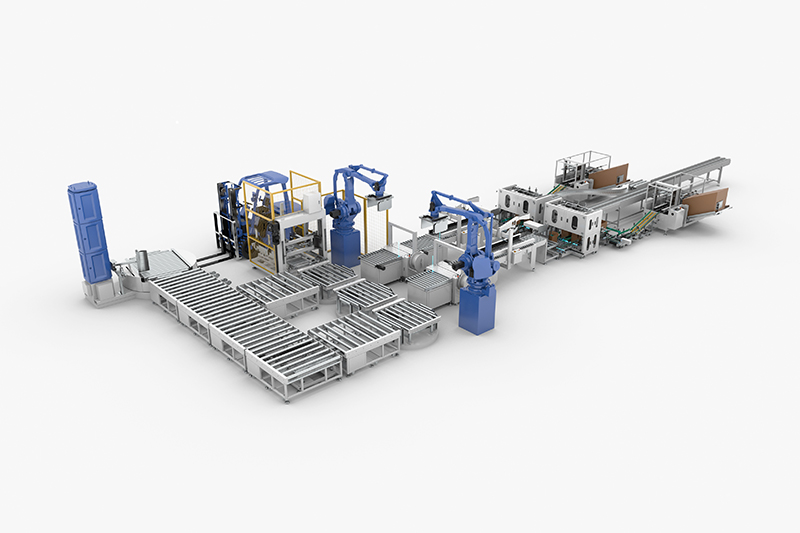

JOYDA TECH’s Industry 4.0 solutions, however, integrate sensors and AI into every machine. These sensors continuously monitor the condition of critical components—vibration levels in a robotic arm, temperature fluctuations in a shrink-wrapping machine, or motor performance in a cartoning machine. AI algorithms analyze this data to predict potential failures before they occur. This allows maintenance to be scheduled proactively at convenient times, minimizing disruption. For instance, the system might detect early signs of wear in a component of a packaging machine for mobile phones, prompting a scheduled replacement during a planned shutdown, rather than an emergency repair during peak production. This predictive capability ensures higher machine availability and significantly reduces the financial burden of unexpected breakdowns.

| Maintenance Type | Characteristics | Impact on ROI |

| Reactive | Unplanned, emergency repairs. | High cost, significant downtime, lost revenue. |

| Time-Based | Scheduled regardless of condition. | Suboptimal, potential for unnecessary costs or missed issues. |

| Predictive (I4.0) | Condition-based, proactive scheduling. | Minimized downtime, optimized costs, extended lifespan. |

3.2 Remote Monitoring and Diagnostics

Another key differentiator is the capability for remote monitoring and diagnostics, a hallmark of Industry 4.0. Traditional systems often require on-site technicians to diagnose issues, which can be time-consuming and expensive, especially for complex machinery or remote locations.

JOYDA TECH’s integrated packaging lines, with their robust software and connectivity, allow for remote access and real-time diagnostics. Expert technicians, like those supported by JOYDA TECH’s technical consultant Chandra Gour, can monitor machine performance, analyze error codes, and even troubleshoot issues from a remote location. For example, if a labeling machine on a perfume packaging line experiences an anomaly, the system can send an alert, and a technician can remotely access diagnostic data to identify the problem. In many cases, issues can be resolved remotely, avoiding the need for an on-site visit. Even when an on-site visit is necessary, the technician arrives with a clear understanding of the problem, reducing repair time. This capability significantly reduces maintenance costs, improves response times, and further contributes to the overall ROI by maximizing uptime.

4. How Does Quality and Waste Reduction Affect ROI?

Are you looking to improve product consistency and minimize costly waste in your packaging operations? Industry 4.0 offers unparalleled precision and control, directly impacting quality and waste reduction, thereby boosting your ROI.

Industry 4.0 packaging lines enhance ROI by ensuring superior product quality through real-time inspection and defect detection, while drastically reducing waste via precise material application and optimized processes. This leads to fewer rejects, less rework, and higher customer satisfaction, directly impacting profitability.

4.1 Enhanced Product Quality and Consistency

One of the most compelling arguments for the ROI of Industry 4.0 packaging lines is their ability to deliver consistently higher product quality. Traditional systems, with their reliance on manual checks or less sophisticated sensors, are more prone to quality variations and undetected defects. For instance, a conventional cartoning machine might occasionally misalign a product, or a hot-melt sealing machine might produce an inconsistent seal, leading to product damage or spoilage.

JOYDA TECH’s Industry 4.0 solutions integrate advanced vision systems, high-precision sensors, and AI-driven quality control at every stage. For example, a vision system on a mobile phone packaging line can inspect every package for correct orientation, label placement, and seal integrity in real-time. If a defect is detected, the system can automatically reject the faulty item or even adjust the machine parameters to prevent recurrence. This ensures that every product, from delicate perfumes to robust sweeping robots, meets stringent quality standards. The result is fewer customer complaints, reduced returns, and a stronger brand reputation, all of which contribute significantly to long-term ROI.

| Quality Metric | Traditional System | Industry 4.0 System (JOYDA TECH) |

| Defect Rate | Higher, often detected post-production. | Significantly lower, real-time detection and prevention. |

| Consistency | Variable, dependent on manual oversight. | High, AI-driven precision and self-correction. |

| Rework | Frequent, costly. | Minimal, defects caught early or prevented. |

| Customer Satisfaction | Potential for complaints. | Higher due to consistent quality. |

4.2 Significant Waste Reduction and Sustainability

Beyond product quality, Industry 4.0 packaging lines offer substantial ROI through significant waste reduction. Traditional systems often lead to material waste due to imprecise application, over-packaging, or undetected errors that result in entire batches being scrapped. Consider a shrink-wrapping machine that uses more film than necessary, or a labeling machine that misprints labels, leading to discarded materials.

JOYDA TECH’s integrated systems employ precision control and optimization algorithms to minimize material consumption. For example, the software can precisely control the amount of hot-melt adhesive applied to each carton, or optimize the cut of shrink film to reduce scrap. Real-time defect detection means that faulty packages are identified and removed immediately, preventing further processing and waste of subsequent materials. This not only translates into direct cost savings on packaging materials but also contributes to sustainability goals, which are increasingly important for brand image and regulatory compliance. By reducing waste across the board—from raw materials to energy—Industry 4.0 packaging lines offer a compelling ROI that benefits both the bottom line and the environment.

5. What is the Long-Term Strategic ROI of Industry 4.0 Packaging?

Are you considering the broader, long-term implications of investing in advanced packaging technology? The strategic ROI of Industry 4.0 extends far beyond immediate cost savings, positioning your business for future growth and resilience.

The long-term strategic ROI of Industry 4.0 packaging lines includes enhanced market competitiveness, unparalleled flexibility for product diversification, improved supply chain resilience, and the ability to adapt to future technological advancements, ensuring sustained growth and a strong market position.

5.1 Enhanced Market Competitiveness and Flexibility

The long-term strategic ROI of Industry 4.0 packaging lines is profoundly linked to enhanced market competitiveness and unparalleled flexibility. In a rapidly evolving market, the ability to quickly adapt to new product demands, packaging formats, and seasonal variations is crucial. Traditional systems often struggle with this, requiring lengthy and costly changeovers or even new equipment for different product lines.

JOYDA TECH’s Industry 4.0 solutions, with their software-driven control and modular design, offer inherent flexibility. A single packaging line can be reconfigured rapidly to handle diverse products—from books and mobile phones to biscuits and perfumes—with minimal downtime. This agility allows businesses to respond quickly to market trends, launch new products faster, and even offer hyper-personalized packaging options. This competitive edge translates into increased market share, stronger customer loyalty, and the ability to capture new revenue streams. The investment in Industry 4.0 is not just about current efficiency; it’s about building a future-proof operation capable of thriving in dynamic market conditions.

5.2 Supply Chain Resilience and Future-Proofing

Finally, the strategic ROI of Industry 4.0 packaging lines includes significantly improved supply chain resilience and future-proofing capabilities. In an increasingly volatile global environment, disruptions can have devastating impacts. Traditional, disconnected systems offer limited visibility and adaptability in such scenarios.

JOYDA TECH’s integrated Industry 4.0 lines, with their real-time data, predictive analytics, and seamless ERP integration, provide end-to-end visibility across the supply chain. This allows businesses to anticipate and mitigate potential disruptions, whether it’s a material shortage or a logistics challenge. For example, if a supply chain issue impacts the availability of a specific packaging material for sweeping robots, the system can quickly identify alternative materials or adjust production schedules to minimize impact. Furthermore, investing in Industry 4.0 means investing in a platform that is inherently scalable and adaptable to future technological advancements, such as advanced AI, quantum computing, or new sustainable materials. This future-proofing ensures that the packaging operation remains at the cutting edge, providing a sustained competitive advantage and a robust foundation for long-term growth.

Conclusion

The debate between Industry 4.0 packaging lines and traditional systems ultimately boils down to a clear and compelling ROI. While traditional systems offer a lower initial investment, their operational inefficiencies, higher waste, and susceptibility to downtime lead to a significantly higher total cost of ownership and limited strategic value. In contrast, Industry 4.0 solutions, like those pioneered by JOYDA TECH, deliver a superior ROI through drastic reductions in operational costs, minimized downtime via predictive maintenance, enhanced product quality, and substantial waste reduction. Beyond these immediate financial gains, the long-term strategic benefits—including enhanced market competitiveness, unparalleled flexibility, and robust supply chain resilience—position businesses for sustained growth and leadership. Investing in Industry 4.0 is not just an expenditure; it’s a strategic imperative that future-proofs operations and unlocks a new era of efficiency and profitability in the packaging industry.