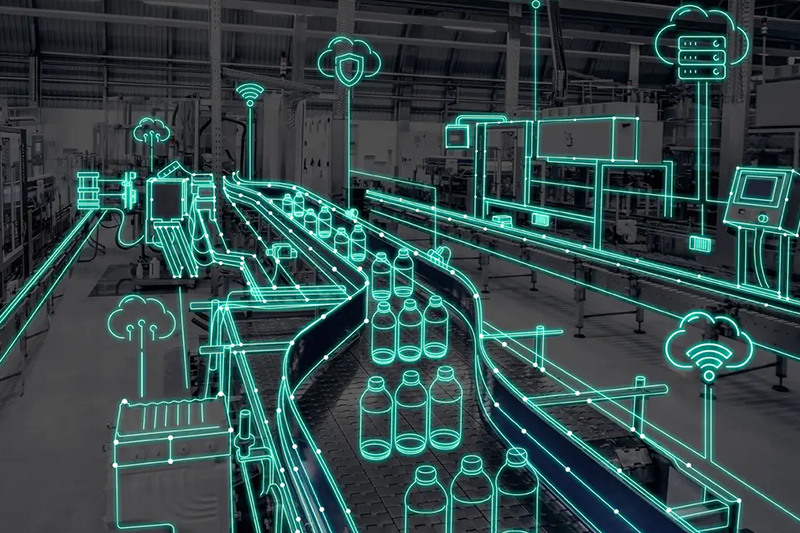

Industry 4.0 is revolutionizing packaging lines by integrating smart technologies like AI, IoT, and automation, enabling unprecedented levels of efficiency, flexibility, and predictive capabilities. This transformation addresses common production challenges, minimizes downtime, and significantly enhances overall operational performance.

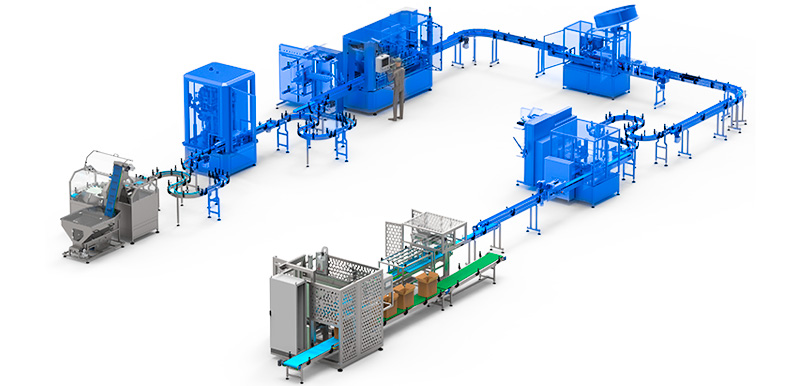

The packaging industry, a critical component of the global supply chain, is constantly seeking innovative ways to improve efficiency, reduce costs, and meet evolving consumer demands. The advent of Industry 4.0 offers a powerful paradigm shift, moving beyond traditional automation to create intelligent, interconnected, and self-optimizing packaging ecosystems. This article delves into how these advanced technologies are reshaping packaging lines, offering a competitive edge to businesses like JOYDA TECH, which are at the forefront of this transformation.

Table of Contents

- What is Industry 4.0 in Packaging?

- How Does Industry 4.0 Enhance Packaging Line Efficiency?

- What Role Does Software Play in Industry 4.0 Packaging?

- How Does Industry 4.0 Improve Quality Control and Reduce Waste?

- What Are the Future Trends of Industry 4.0 in Packaging?

1. What is Industry 4.0 in Packaging?

Are you wondering how the latest technological revolution applies to the intricate world of packaging? Industry 4.0 in packaging signifies the integration of advanced digital technologies into every facet of the packaging process, creating smart, interconnected, and highly autonomous production environments.

Industry 4.0 in packaging refers to the comprehensive digitalization and intelligent networking of machines, systems, and processes within a packaging line, leveraging technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), big data analytics, and advanced robotics to achieve real-time optimization and predictive capabilities.

1.1 The Theoretical Basis of Industry 4.0 in Packaging

The theoretical foundation of Industry 4.0 rests on several core principles: interoperability, transparency, technical assistance, and decentralized decisions. In packaging, interoperability means machines, sensors, and human operators can communicate seamlessly. For instance, a smart hot-melt sealing machine from JOYDA TECH can exchange data with a robotic palletizer, ensuring a smooth flow of products. Transparency involves creating a virtual copy of the physical world through sensor data, allowing for real-time monitoring of every package’s journey. Technical assistance empowers systems to support humans with complex tasks or even automate dangerous ones, such as precise robotic handling of delicate items like perfume bottles or mobile phones. Finally, decentralized decisions enable cyber-physical systems to make autonomous choices, for example, a shrink-wrapping machine adjusting its temperature settings based on real-time film properties without human intervention. This multi-angle analysis highlights how these principles converge to create a highly responsive and adaptive packaging environment.

| Principle | Description | Packaging Application Example |

| Interoperability | Seamless communication between systems. | JOYDA TECH’s cartoning machine communicating with an ERP system. |

| Transparency | Real-time virtual representation of physical processes. | Sensors tracking every book on a packaging line. |

| Technical Assistance | Systems aiding or automating human tasks. | Robotic arms assisting in precise product placement. |

| Decentralized Decisions | Autonomous decision-making by cyber-physical systems. | A labeling machine self-adjusting for different product sizes. |

1.2 Design Trade-offs and Practical Impacts

Implementing Industry 4.0 in packaging involves careful design trade-offs. While the initial investment in advanced sensors, AI software, and integrated systems can be substantial, the long-term benefits often outweigh these costs. For example, integrating JOYDA TECH’s proprietary software with a client’s ERP system offers unparalleled data flow and real-time monitoring, but requires careful planning for data security and system compatibility. The practical impacts are profound: reduced human error, increased throughput, and enhanced product quality. Consider a packaging line for delicate items like mobile phones; the precision offered by advanced robotics and vision systems significantly reduces damage rates compared to manual handling. Another example is the packaging of biscuits or chocolates, where predictive maintenance, enabled by IoT sensors, can anticipate machine failures in a hot-melt sealing machine, preventing costly downtime and product spoilage. These systems also allow for greater flexibility, enabling quick changeovers between different product types, a crucial advantage in today’s diverse market.

2. How Does Industry 4.0 Enhance Packaging Line Efficiency?

Are you looking for ways to dramatically boost your packaging line’s output and reduce operational bottlenecks? Industry 4.0 technologies are specifically designed to optimize every stage of the packaging process, leading to significant gains in efficiency and productivity.

Industry 4.0 enhances packaging line efficiency through real-time data collection and analysis, predictive maintenance, optimized resource allocation, and autonomous operations, minimizing downtime, increasing throughput, and ensuring consistent quality across the entire production cycle.

2.1 Real-time Monitoring and Data-Driven Optimization

The core of Industry 4.0’s efficiency gains lies in its ability to collect and analyze vast amounts of data in real-time. Every machine, from a hot-melt sealing machine to a robotic palletizer, is equipped with sensors that feed data into a central system. JOYDA TECH’s internal software, for instance, can monitor the operational status, energy consumption, and performance metrics of an entire packaging line for products like books or household appliances. This data allows for immediate identification of bottlenecks or inefficiencies. For example, if a shrink-wrapping machine is consistently running slower than optimal, the system can flag it, allowing operators to investigate and rectify the issue promptly. This proactive approach, driven by data, moves beyond reactive problem-solving, ensuring that the line operates at its peak potential. The ability to visualize the entire process through a digital twin further aids in understanding complex interactions and optimizing workflows.

| Data Point | Impact on Efficiency | Example Application |

| Throughput Rate | Identifies bottlenecks. | Monitoring units per minute on a cartoning line. |

| Energy Consumption | Optimizes power usage. | Adjusting settings on a hot-melt sealing machine. |

| Machine Uptime | Reduces downtime. | Predictive alerts for maintenance on a labeling machine. |

| Error Rate | Improves quality and reduces rework. | Detecting misaligned labels on perfume bottles. |

2.2 Predictive Maintenance and Downtime Reduction

One of the most impactful applications of Industry 4.0 in packaging is predictive maintenance. Instead of adhering to fixed maintenance schedules or waiting for a machine to break down, sensors continuously monitor the health of components. For example, vibration sensors on a robotic arm used for packaging mobile phones can detect early signs of wear and tear. Similarly, temperature sensors on a hot-melt sealing machine can predict potential issues with the heating elements. JOYDA TECH’s systems, integrated with these sensors, can then schedule maintenance proactively, precisely when it’s needed, before a failure occurs. This approach drastically reduces unplanned downtime, which is a major cost driver in packaging operations. By minimizing disruptions, packaging lines for products like biscuits or sweeping robots can maintain continuous operation, ensuring timely delivery and maximizing overall equipment effectiveness (OEE). This not only saves money on emergency repairs but also extends the lifespan of the machinery.

3. What Role Does Software Play in Industry 4.0 Packaging?

Have you considered how intelligent software can be the brain behind your highly efficient packaging operations? In the realm of Industry 4.0, software is not just a tool; it’s the central nervous system that orchestrates every aspect of a smart packaging line.

Software is the foundational element of Industry 4.0 packaging, enabling seamless integration, real-time data analysis, autonomous decision-making, and connectivity with enterprise systems, thereby transforming raw data into actionable insights for optimized production, predictive maintenance, and enhanced operational control.

3.1 Seamless Integration with ERP Systems

The true power of Industry 4.0 software lies in its ability to integrate seamlessly with existing enterprise resource planning (ERP) systems. JOYDA TECH’s independently developed software is a prime example, designed to interface effortlessly with a client’s ERP. This integration allows for a continuous flow of data, from order entry in the ERP to real-time production updates on the packaging line. For instance, an order for a specific quantity of packaged perfumes can trigger the packaging line to adjust its settings automatically, retrieve the correct labels, and track the progress of each batch. This eliminates manual data entry, reduces errors, and provides a holistic view of the entire supply chain. The ability to connect packaging operations directly to business planning ensures that production is always aligned with demand, minimizing waste and maximizing responsiveness. This level of data fluidity is critical for achieving the agility and efficiency promised by Industry 4.0.

| Integration Benefit | Description | Practical Impact |

| Data Flow | Real-time exchange of information. | Automated inventory updates for packaging materials. |

| Production Planning | Aligning output with demand. | Packaging line adjusts to new order quantities instantly. |

| Quality Assurance | Tracking product quality from start to finish. | Linking batch numbers to specific packaging parameters. |

| Cost Control | Monitoring resource consumption. | Real-time tracking of hot-melt glue usage per package. |

3.2 Autonomous Control and Optimization

Beyond data integration, Industry 4.0 software empowers packaging lines with autonomous control and self-optimization capabilities. Using AI and machine learning algorithms, the software can analyze historical data and real-time inputs to make intelligent decisions without human intervention. Consider a packaging line handling various products like books, mobile phones, or different types of food. JOYDA TECH’s software can automatically adjust the settings of a shrink-wrapping machine or a hot-melt sealing machine based on the specific product being processed, optimizing speed, temperature, and pressure for each item. This not only ensures consistent quality but also significantly reduces changeover times. Furthermore, the software can perform predictive maintenance, as discussed earlier, by analyzing sensor data and scheduling interventions. This level of autonomy transforms packaging lines from mere production units into intelligent, self-managing systems that continuously learn and improve, leading to unparalleled efficiency and reliability.

4. How Does Industry 4.0 Improve Quality Control and Reduce Waste?

Are you struggling with inconsistent product quality or excessive material waste on your packaging line? Industry 4.0 offers sophisticated solutions to elevate quality control and dramatically minimize waste, ensuring every package meets the highest standards.

Industry 4.0 significantly improves quality control and reduces waste by implementing real-time inspection systems, predictive analytics for defect prevention, precise material usage optimization, and traceability, ensuring consistent product quality while minimizing material consumption and rework.

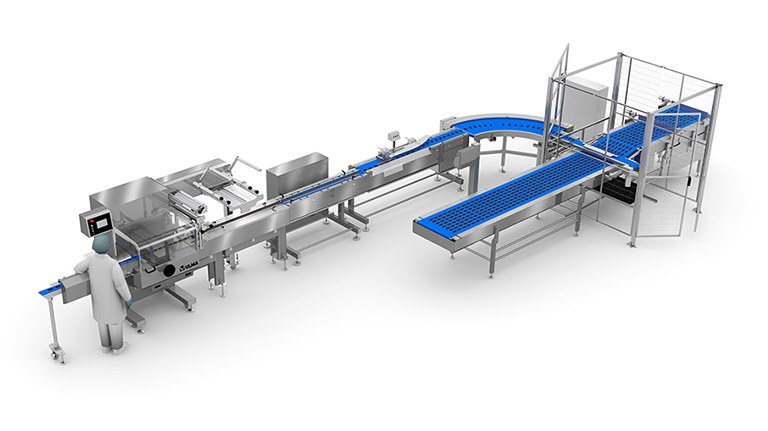

4.1 Real-time Inspection and Defect Prevention

One of the most significant contributions of Industry 4.0 to packaging is its ability to implement real-time, high-precision quality control. Traditional quality checks often involve sampling or post-production inspection, which can lead to significant waste if defects are only discovered after a large batch has been processed. With Industry 4.0, advanced vision systems and sensors are integrated directly into the packaging line. For example, a camera system on a JOYDA TECH labeling machine can instantly detect misaligned labels on perfume bottles or incorrect barcodes on mobile phone packaging. Similarly, sensors on a hot-melt sealing machine can verify the integrity of every seal on a biscuit package. If a defect is detected, the system can immediately reject the faulty item, or even better, adjust the machine parameters to prevent further defects. This proactive approach, enabled by AI-driven analysis of visual and sensor data, ensures that only perfectly packaged products proceed down the line, drastically reducing rework and waste.

| Quality Control Feature | Description | Example Application |

| Vision Systems | Automated visual inspection for defects. | Checking for torn shrink wrap on a product. |

| Sensor Integration | Monitoring physical parameters. | Verifying correct fill levels in a cartoning machine. |

| AI-driven Analysis | Identifying patterns and predicting issues. | Predicting adhesive failures in hot-melt sealing. |

| Automated Rejection | Removing faulty products immediately. | Diverting incorrectly labeled books from the line. |

4.2 Material Optimization and Traceability

Industry 4.0 also plays a crucial role in optimizing material usage and enhancing traceability, directly contributing to waste reduction. Through precise control and monitoring, packaging lines can minimize the consumption of materials like film for shrink-wrapping, glue for hot-melt sealing, or cardboard for cartoning. For instance, JOYDA TECH’s systems can precisely control the amount of hot-melt adhesive applied to each carton, preventing overuse and ensuring optimal adhesion. This not only saves material costs but also reduces environmental impact. Furthermore, comprehensive traceability, enabled by unique identifiers (like QR codes or RFID tags) on each package, allows for end-to-end tracking of products. If a quality issue arises, the specific batch, production date, and even the machine that processed it can be identified instantly. This granular level of traceability is invaluable for product recalls, quality audits, and understanding the root cause of any packaging defect, ultimately leading to more efficient problem-solving and less overall waste.

5. What Are the Future Trends of Industry 4.0 in Packaging?

Are you curious about what’s next for smart packaging lines and how they will continue to evolve? The future of Industry 4.0 in packaging promises even greater levels of autonomy, intelligence, and sustainability, driven by continuous innovation and technological advancements.

The future trends of Industry 4.0 in packaging include increased adoption of collaborative robotics, advanced AI for hyper-personalization and predictive analytics, greater emphasis on sustainable and circular economy practices, and the development of fully autonomous, self-optimizing packaging factories.

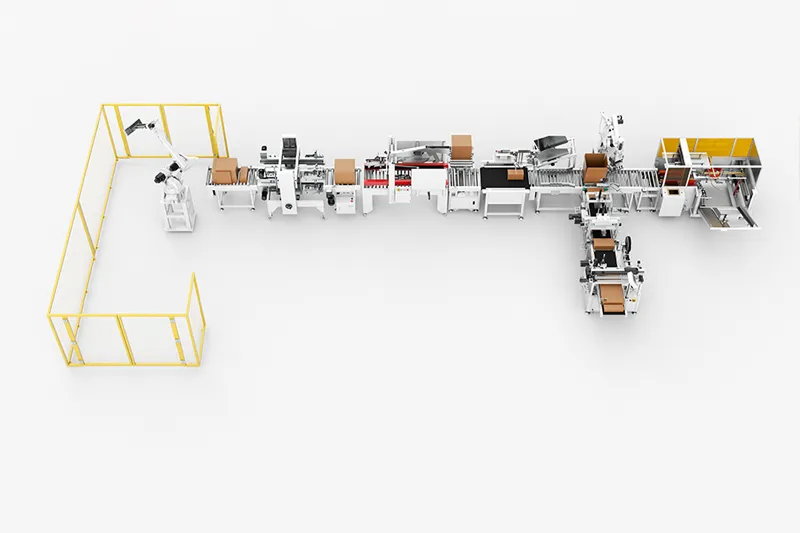

5.1 Collaborative Robotics and Human-Machine Interaction

The next wave of Industry 4.0 in packaging will see an even greater integration of collaborative robotics (cobots). Unlike traditional industrial robots, cobots are designed to work safely alongside human operators, enhancing productivity without requiring extensive safety caging. For example, a cobot could assist a human in precisely placing delicate items like perfume bottles into a cartoning machine, reducing strain on the human while maintaining high accuracy. JOYDA TECH’s focus on advanced automation and system integration positions it well to leverage these technologies. This human-machine interaction will evolve to be more intuitive, with AI-powered interfaces allowing operators to communicate with machines using natural language or gestures. The practical impact is a more flexible workforce, where humans focus on complex problem-solving and oversight, while cobots handle repetitive or physically demanding tasks, leading to higher job satisfaction and overall efficiency.

5.2 Hyper-Personalization and Sustainable Packaging

The future of Industry 4.0 in packaging will also be heavily influenced by consumer demand for hyper-personalization and the urgent need for sustainable practices. Advanced AI and flexible automation will enable packaging lines to produce highly customized packages on demand, even for small batches, without significant changeover times. Imagine a packaging line for chocolates that can print a unique message or design on each individual wrapper based on customer preferences. This level of flexibility, driven by data from e-commerce platforms, will become standard. Simultaneously, Industry 4.0 will be instrumental in achieving sustainability goals. Smart sensors and AI will optimize material usage even further, identify opportunities for using recycled or biodegradable materials, and facilitate the tracking of packaging through a circular economy model. JOYDA TECH’s commitment to efficient and robust packaging solutions will extend to incorporating these sustainable innovations, ensuring that packaging lines are not only intelligent but also environmentally responsible. This includes optimizing shrink-wrapping processes to minimize film usage and developing hot-melt sealing solutions that are compatible with recyclable materials.

Conclusion

Industry 4.0 is not merely an upgrade; it’s a fundamental transformation of packaging lines, moving them from isolated machines to interconnected, intelligent ecosystems. By embracing technologies like IoT, AI, and advanced automation, companies like JOYDA TECH are enabling unprecedented levels of efficiency, quality control, and flexibility. From real-time data-driven optimization and predictive maintenance to seamless ERP integration and autonomous operations, Industry 4.0 addresses critical challenges in the packaging sector. Looking ahead, the continued evolution of collaborative robotics, hyper-personalization, and sustainable practices will further redefine what’s possible, ensuring that packaging lines are not only productive but also adaptive, resilient, and environmentally conscious. For businesses seeking to thrive in a competitive landscape, adopting Industry 4.0 is no longer an option but a strategic imperative.