Integrating checkweighers into your packaging workflow is crucial for maximizing efficiency by precisely weighing every product, ensuring compliance, eliminating costly product giveaways, and preventing underfilled packages. This smart investment provides 100% quality inspection, real-time data for process improvement, and seamless integration for a streamlined, profitable operation.

Are giveaway products or underfilled packages eating into your profits? In today’s competitive market, even small inconsistencies in product weight can lead to significant financial losses, regulatory fines, and damaged brand reputation. Manual checks are slow, error-prone, and simply can’t keep up with modern production speeds. This article will explore how integrating a checkweigher into your packaging workflow can solve these problems, offering benefits far beyond simple weight verification. Discover how Joyda Totalpack’s checkweigher solutions can transform your quality control and boost your bottom line.

Table of Contents

- What is a Checkweigher and How Does it Work?

- Key Benefits Beyond Simple Weight Checking

- Seamless Integration with Your Existing Line

- Choosing the Right Checkweigher

- Checkweighers: A Smart Investment

1. What is a Checkweigher and How Does it Work?

Ever wondered how packaging lines ensure every product has the correct weight at lightning speed? It’s all thanks to the checkweigher.

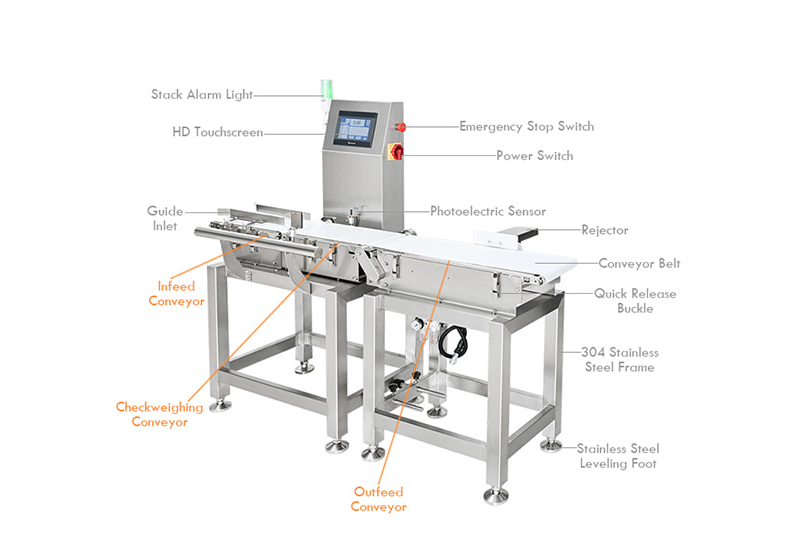

A checkweigher is an automated quality control device that rapidly weighs every single product on a production line. It compares each item’s weight against pre-set target ranges, then automatically accepts compliant products and rejects those that are under or overweight, ensuring speed and accuracy.

1.1 Simple Explanation: Weighing, Comparing, and Rejection

At its core, a checkweigher performs three rapid steps: weighing, comparing, and rejecting. As products move along the conveyor, they pass over a high-precision load cell. This cell instantly measures the product’s exact weight. This measured weight is then compared to pre-programmed upper and lower weight limits. If the product falls within this acceptable range, it continues down the line. If it’s too light (underweight) or too heavy (overweight), the checkweigher activates a rejection mechanism—such as a pneumatic pusher, an air blast, or a diverter arm—to remove the faulty item from the production flow. This entire process happens in milliseconds, ensuring no slowdowns. For example, in a line packaging coffee bags, the checkweigher quickly verifies each bag’s weight, rejecting any that are underfilled or overfilled due to machine error.

| Checkweigher Step | Action | Outcome |

| Weighing | High-speed, precise measurement. | Accurate weight data for every product. |

| Comparing | Checks weight against target range. | Identifies compliant vs. non-compliant items. |

| Rejection | Automatic removal of faulty products. | Prevents costly errors and ensures quality. |

1.2 Emphasizing Speed and Accuracy

The true power of a checkweigher lies in its unparalleled speed and accuracy. Unlike manual spot checks, which are slow and prone to human error, a checkweigher provides 100% inspection at full production line speeds. Modern checkweighers can process hundreds of items per minute with extreme precision, often down to fractions of a gram. This means every single product leaving your facility is verified for correct weight. For instance, in a high-volume snack food production line, a checkweigher can accurately weigh thousands of chip bags per hour, ensuring each one meets the declared net weight. This combination of speed and accuracy is critical for maintaining high throughput while simultaneously guaranteeing product quality and compliance, directly impacting your bottom line by eliminating waste and ensuring customer satisfaction.

2. Key Benefits Beyond Simple Weight Checking

Think checkweighers only check weight? Think again. Their advantages extend far beyond basic verification, impacting compliance, data, and overall quality.

Beyond simple weight checking, checkweighers ensure legal weight compliance, collect invaluable production data for process optimization and traceability, and provide 100% inspection to guarantee no faulty products reach customers, safeguarding profits and brand reputation.

2.1 Compliance: Meeting Legal Weight Regulations

One of the most critical benefits of integrating a checkweigher is ensuring strict compliance with legal weight regulations. Governments worldwide impose stringent rules on product net weight to protect consumers from deceptive practices. Failing to meet these “average weight” or “minimum weight” regulations can result in hefty fines, product recalls, and severe damage to your brand’s reputation. A checkweigher provides continuous, verifiable proof that your products meet these standards. For example, a pharmaceutical company packaging pills must adhere to extremely tight weight tolerances for each bottle. A checkweigher provides the necessary precision and documentation to demonstrate compliance, avoiding legal repercussions and ensuring patient safety. This proactive approach to compliance is a non-negotiable aspect of modern manufacturing.

2.2 Data & Traceability: Collecting Production Data for Process Improvement

Modern checkweighers are not just scales; they are sophisticated data collection hubs. They can record the weight of every single product, timestamp it, and often integrate with your factory’s Manufacturing Execution System (MES) or Enterprise Resource Planning (ERP) system. This rich stream of data provides invaluable insights into your production process. By analyzing weight trends, you can identify issues like inconsistent filling machine performance, material density variations, or even packaging defects. For instance, if a checkweigher consistently detects slightly underweight packages from a specific filling head, it signals a need for calibration or maintenance. This data enables predictive maintenance, process optimization, and enhanced traceability, allowing you to pinpoint the exact time and conditions under which any product was packaged. Joyda Totalpack’s checkweighers come with advanced software for seamless data logging and integration.

| Data Point | Insight Provided | Impact on Efficiency |

| Average Weight | Overall filling accuracy. | Reduces product giveaway. |

| Standard Deviation | Consistency of filling process. | Improves process stability. |

| Rejection Rate | Frequency of errors. | Highlights areas for immediate improvement. |

| Time-stamped Data | Traceability for specific batches. | Aids in recalls, quality audits. |

2.3 100% Inspection: Ensuring No Faulty Product Reaches the Customer

Perhaps the most compelling benefit is the guarantee of 100% inspection. Unlike manual sampling, which only checks a small percentage of products, a checkweigher inspects every single item. This means you can be confident that no underfilled, overweight, or otherwise faulty product (related to weight) will ever reach your customers. This level of assurance is critical for maintaining brand trust and customer loyalty. Imagine a cosmetic company packaging high-value creams; an underfilled jar would be a significant customer disappointment. The checkweigher ensures every jar contains the precise amount, protecting both the customer experience and the brand’s premium image. This unwavering commitment to quality translates directly into fewer customer complaints, reduced returns, and a stronger market reputation.

3. Seamless Integration with Your Existing Line

Worried about fitting new technology into your current setup? Checkweighers are designed for smooth integration, enhancing your existing workflow.

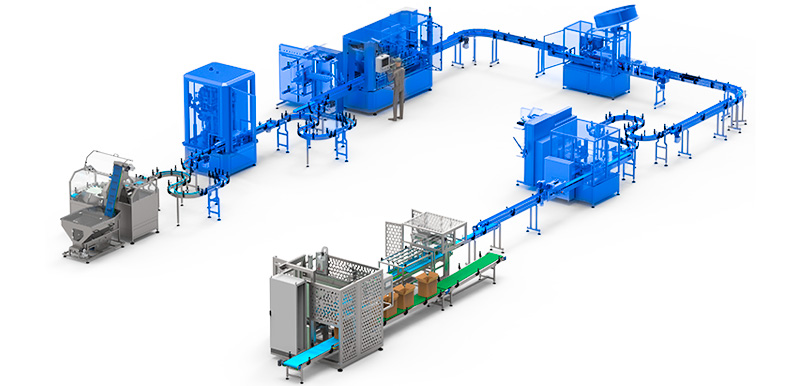

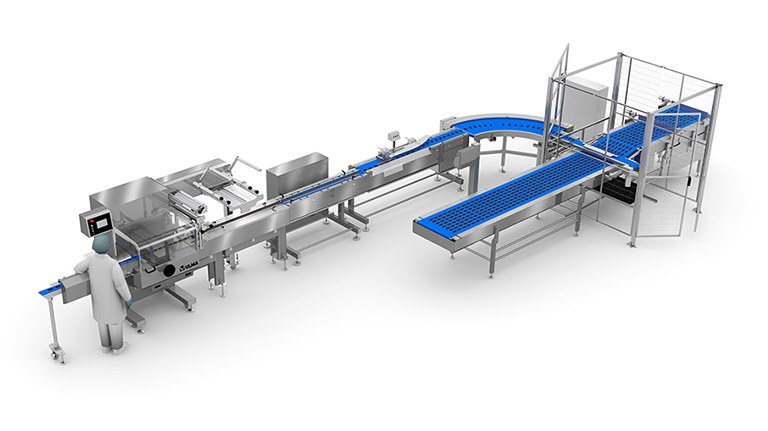

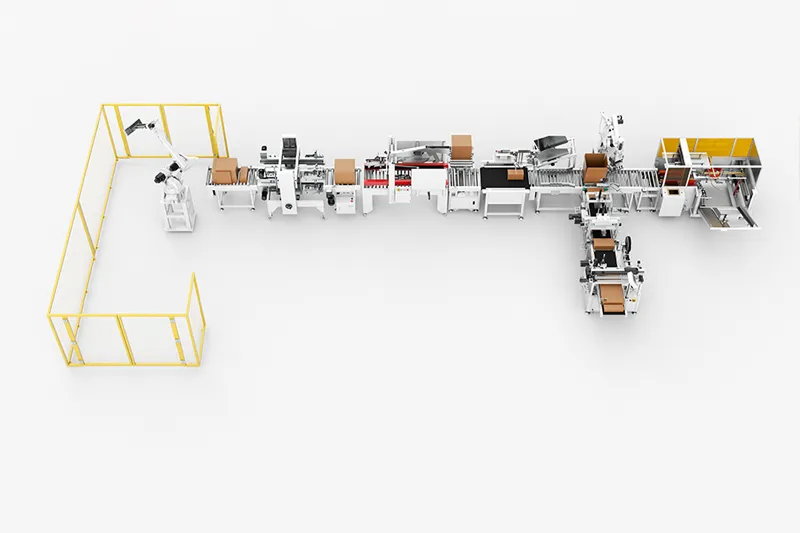

Checkweighers seamlessly integrate into existing packaging lines, typically positioned between the filling/packing machine and the case sealer. They communicate with other equipment, such as labeling machines for data logging or upstream fillers for feedback control, ensuring a cohesive and optimized workflow.

3.1 Fitting Between Filling/Packing and Case Sealer

Integrating a checkweigher into your existing packaging line is surprisingly straightforward. Its ideal placement is typically immediately after the filling or packing machine and before the case sealer. This strategic position allows it to verify the weight of the product after it has been filled into its primary packaging but before that packaging is sealed into a larger case. This ensures that any weight discrepancies are caught at the earliest possible stage, preventing further processing of a faulty item. For example, in a line packaging frozen vegetables, the checkweigher would be placed after the bagger and before the bags are grouped for case packing. Joyda Totalpack’s checkweighers are designed with flexible conveyor heights and configurations to easily slot into various line layouts, minimizing disruption during installation.

3.2 Communication Protocols and Data Logging

Modern checkweighers are not isolated units; they are intelligent devices capable of robust communication with other machines on your line. They often utilize standard industrial communication protocols (e.g., Ethernet/IP, Profinet, Modbus TCP) to exchange data. This allows for critical functions like:

- Feedback Control: The checkweigher can send real-time weight data back to the upstream filling machine. If it detects a trend of slightly underweight products, it can signal the filler to adjust its dosage, proactively correcting the issue before more products are rejected.

- Data Logging with Labeling Machines: Weight data, along with timestamps and product IDs, can be sent to a labeling machine. This allows for printing variable data on labels, such as individual package weight or batch-specific quality codes, enhancing traceability.

- MES/ERP Integration: Connecting to your central manufacturing systems allows for comprehensive data analysis, production reporting, and inventory management.

For instance, in a line packaging pharmaceutical bottles, the checkweigher can communicate with the labeling machine to print a unique serial number and verified weight on each bottle’s label, crucial for regulatory compliance and anti-counterfeiting measures. This interconnectedness transforms your line into a truly smart and responsive system.

4. Choosing the Right Checkweigher

Selecting the perfect checkweigher isn’t a one-size-fits-all decision. It depends on your specific product and production needs.

Choosing the right checkweigher involves evaluating factors like required speed (items per minute), the product’s weight range (min/max), and the specific product type (e.g., dry, liquid, fragile). These considerations ensure the checkweigher accurately meets your production demands and integrates effectively.

4.1 Factors: Speed, Weight Range, and Product Type

Selecting the optimal checkweigher requires careful consideration of several key factors to ensure it perfectly matches your production needs:

- Speed (Items Per Minute): This is paramount. The checkweigher must be able to keep pace with your upstream filling and packing machines without creating a bottleneck. High-speed lines require checkweighers with faster conveyor belts and processing capabilities. For example, a line packaging small candy bars at 300 pieces per minute needs a much faster checkweigher than one handling large bags of pet food at 60 pieces per minute.

- Weight Range (Minimum/Maximum): The checkweigher’s load cell and mechanics are designed for a specific weight range. You need a machine that can accurately measure both your lightest and heaviest products. A checkweigher designed for grams won’t work for kilograms, and vice-versa.

- Product Type and Characteristics:

- Dry vs. Liquid: Liquids can slosh, requiring specific conveyor designs and stabilization.

- Fragile vs. Robust: Delicate items like glass bottles need gentle handling.

- Shape and Stability: Round or unstable products might need special guides or longer weighing platforms.

- Environment: Dusty, wet, or corrosive environments require specific IP ratings and material construction (e.g., stainless steel for food processing).

Joyda Totalpack offers a range of checkweigher models, each optimized for different applications, ensuring you find the perfect fit for your unique product and production environment.

5. Checkweighers: A Smart Investment

Still seeing checkweighers as just another cost? Reframe your perspective. They are a strategic asset that delivers tangible returns.

Positioning the checkweigher as a smart investment, not just a cost, highlights its long-term value. It delivers significant ROI by preventing product giveaway, avoiding fines, reducing waste, enhancing brand reputation, and providing critical data for continuous process improvement and operational efficiency.

5.1 Long-Term Value and ROI

While a checkweigher represents an initial investment, its long-term value and return on investment (ROI) are substantial. Consider the cumulative savings:

- Reduced Product Giveaway: Even a fraction of a gram overfill per package, multiplied by thousands of units daily, amounts to significant material waste. A checkweigher precisely controls this, saving raw material costs.

- Avoided Fines and Recalls: Compliance with weight regulations prevents costly fines and the devastating financial and reputational impact of product recalls due to incorrect weight.

- Lower Labor Costs: Automating 100% weight inspection frees up personnel from manual checks, allowing them to focus on higher-value tasks.

- Enhanced Brand Reputation: Consistent product quality builds customer trust and loyalty, leading to repeat business and positive word-of-mouth.

- Process Optimization: The data collected by checkweighers enables continuous improvement of upstream processes, further boosting efficiency and reducing waste.

For example, a company packaging expensive cosmetics might save tens of thousands of dollars annually just by eliminating slight overfills, quickly recouping the checkweigher’s cost. A checkweigher is an investment in quality, efficiency, and profitability.

Conclusion:

Integrating a checkweigher into your packaging workflow is a strategic move that goes far beyond simple weight verification. It’s a powerful tool for ensuring compliance, eliminating costly product giveaways, and guaranteeing 100% quality inspection. From its rapid weighing and rejection process to its seamless integration capabilities and invaluable data collection, a checkweigher is a cornerstone of modern, efficient, and profitable packaging operations. It’s not just a cost; it’s a smart investment that protects your profits, enhances your brand, and future-proofs your production line.